TM 5-3895-359-14&P

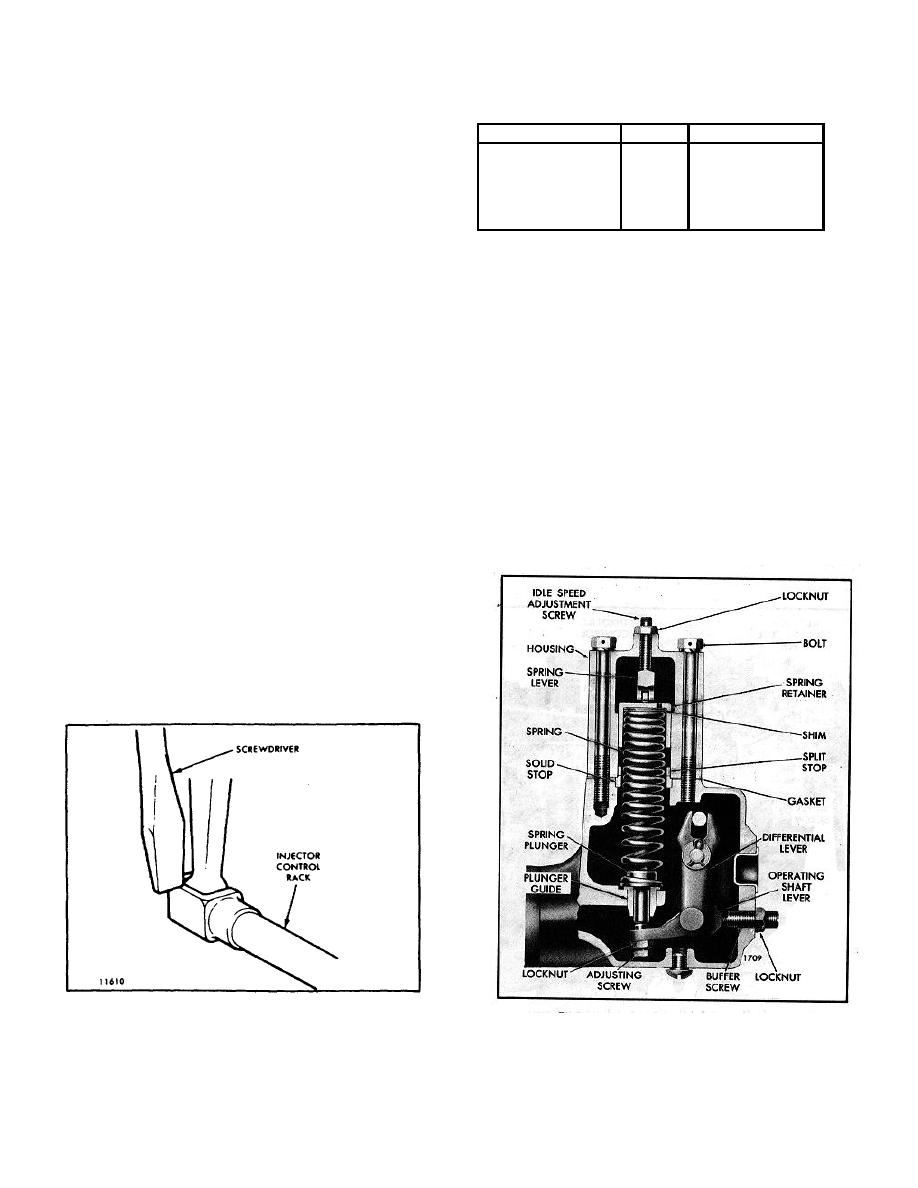

7. Manually hold the No. 1 injector rack in the full fuel

position and turn down the inner adjusting screw (Fig. 2)

Full Load Speed

Stops

Shims

of the No. 2 injector until the injector rack has moved

1200 to 1425 rpm

2

Up to .325"

into full fuel position and the inner adjusting screw is

1426 to 1825 rpm

1

Up to .325"

bottomed on the injector control tube. Turn the outer

Amount Required

adjusting screw down until it bottoms lightly on the

1826 to 2100 rpm

0

to get necessary

injector control tube. Then alternately tighten both the

speed.

inner and outer adjusting screws until tight.

TABLE 1

8. Recheck the No. 1 injector rack to be sure that it has

remained snug on the ball end of the rack control lever

A split stop can only be used with a solid stop (Fig. 6).

while positioning the No. 2 injector rack. If the rack of

the No. 1 injector has become loose, back off slightly

4. Install the variable speed spring housing and recheck

the inner adjusting screw on No. 2 injector control lever.

the maximum no-load speed.

Tighten the outer adjusting screw.

5. If required, add shims to obtain the necessary

9. Position the remaining injector rack control levers as

operating speed.

outlined in Steps 7 and 8.

NOTE:

If the maximum no-load

Adjust /Maximum No-Load Speed

speed is raised or lowered more than

The maximum no-load speed on engines equipped with

50 rpm by the installation or removal

variable speed governors must not be less than 125 rpm

of the governor shims, the governor

or more than 150 rpm above the recommended full load

gap should be rechecked.

speed.

If readjustment of the governor gap is required, the

With a hand tachometer, determine the maximum no

position of the injector racks must be rechecked.

load speed of the engine then, make the following

adjustments, if required:

1. Refer to Fig. 3 and disconnect the booster spring.

2. Remove the two bolts and withdraw the variable

speed spring housing and the variable speed spring

plunger from inside the spring housing.

Fig. 5 - Checking Injector Control Rack "Spring"

Fig. 6 - Location of Stops and Shims

3. Refer to Table 1 and Fig. 6 and determine the stop or

shim required for the desired full load speed.

10-10-6