TM 5-3895-359-14&P

VARIABLE SPEED MECHANICAL GOVERNOR AND

INJECTOR RACK CONTROL ADJUSTMENT

After adjusting the exhaust valves and timing the fuel

injectors, adjust the governor and the injector rack

7. Hook the torsion retracting spring on the special

control levers.

cover screw and the stop lever (Fig. 2).

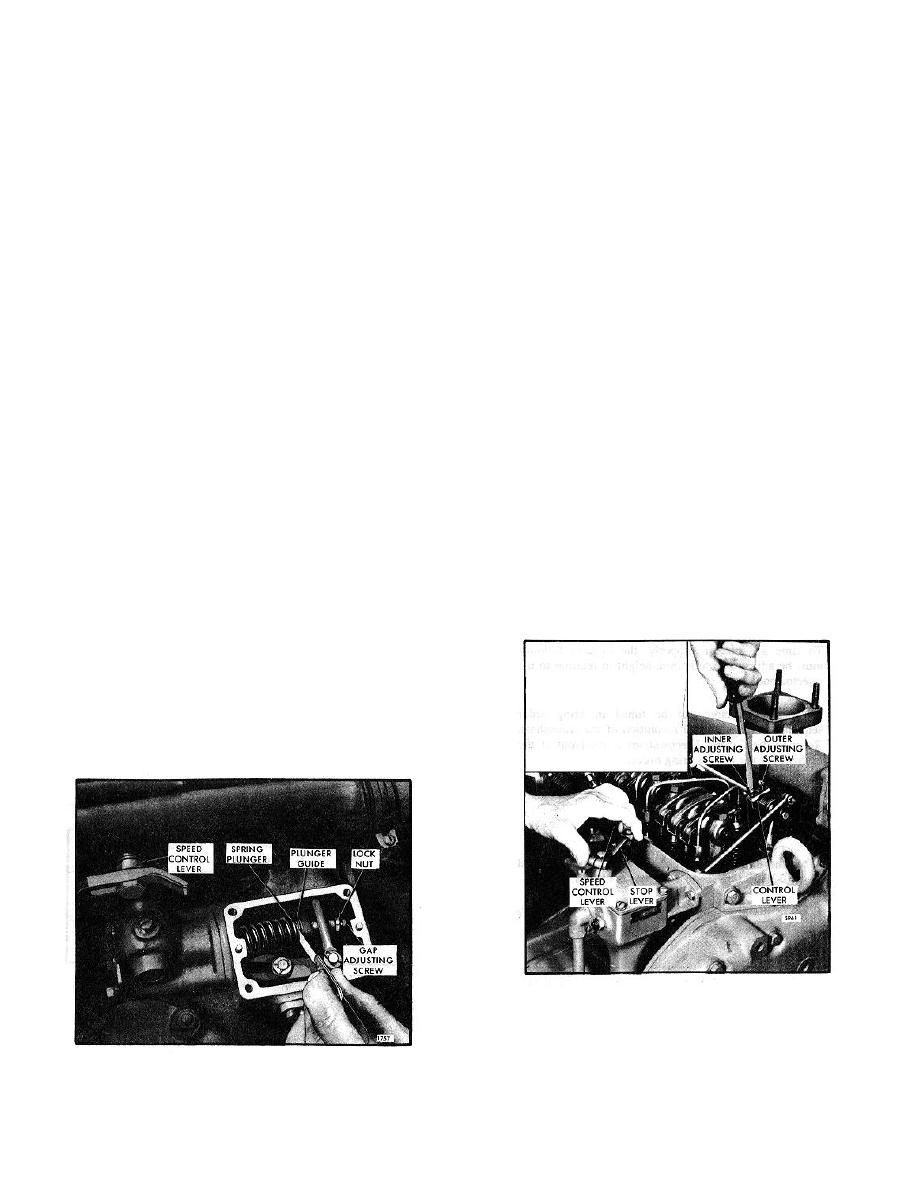

Adjust Governor Gap

Position Injector Rack Control Levers

With the engine stopped, adjust the governor gap as

The position of the injector control rack levers must be

follows:

correctly set in relation to the governor.

1. Disconnect any linkage attached to the governor

Their position determines the amount of fuel injected

levers.

into each cylinder and ensures equal distribution of the

load.

2. Remove the governor cover.

Properly positioned injector rack control levers with the

3. Place the speed control lever (Fig.1) in the maximum

engine at full load will result in the following:

speed position.

Speed control lever at the maximum speed position.

4. Insert a .006" feeler gage between the spring

plunger and the plunger guide. If required, loosen the

Stop lever in the RUN position.

lock nut and turn the adjusting screw in or out until a

slight drag is noted on the feeler gage.

5. Hold the adjusting screw and tighten the lock nut.

Check the gap, and reset it, if necessary.

6. Secure the governor cover to the governor housing

with three regular screws, one special screw and lock

washers.

Fig. 2 - Positioning No. 1 injector Rack Control

Lever

Fig. 1 - Adjusting Governor Cap

10-10-4