TM 5-3895-359-14&P

Sintered bronze bearings used in these motors have a

dull finish, as compared to the early type machined, cast

bronze bearings which had a shiny finish.

Before pressing the bearing into place, dip it in SAE No.

oil. Also, tangent wicks should be soaked with SAE No.

20 oil. Insert the wick into place first, and then press in

the bearing.

DO NOT DRILL, REAM OR MACHINE sintered bearings

in any way! These bearings are supplied to size. If

drilled or reamed, the I.D., (inside diameter) will be too

large, also the bearing pores will be sealed over.

It is not necessary to cross-drill a sintered bearing when

used with a tangent wick. Because the bearing is so

highly porous, oil from the wick touching the outside

bearing surface will bleed through and lubricate the

shaft.

Middle bearings are support bearings and prevent

armature deflection during cranking. As compared to

end frame bearings, the clearance between middle

bearing and shaft is large and the clearance provides a

loose fit when assembled.

Pinion Clearance

To check pinion or drive clearance follow the steps

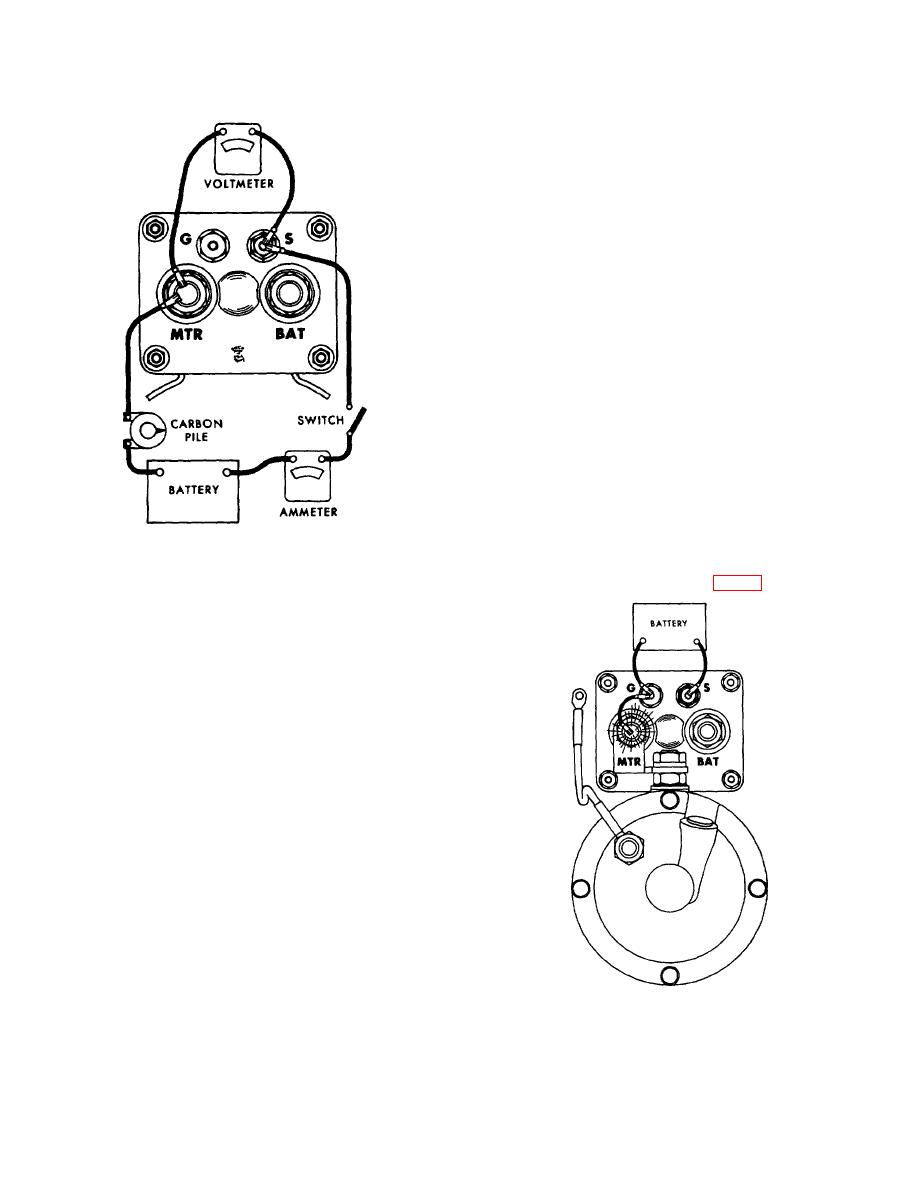

Fig. 6 - Checking Solenoid Pull-In Winding.

listed below.

The specified pull-in voltage is 5 volts and the pull-in

1. Make connections as shown in Fig. 7.

current is 28 to 35.7 amperes.

To check for grounds, move battery lead from "G" (Fig. )

and from "MTR" (Fig. 10) to solenoid case, (not shown).

meter should read zero. If not, winding is grounded.

NOTE: If needed to reduce the voltage to the specified

value, connect the carbon pile between the battery and

the "MTR" terminal as shown. If the carbon pile is not

needed, connect a jumper directly from the battery to

the "MTR" terminal.

CAUTION: To prevent overheating, do not leave the

pull-in winding energized more than 15 seconds. e

current draw will decrease as the winding temperature

increases.

Reassembly

To reassemble the end frame with brushes onto the field

frame, pull the armature out of the field frame just far

enough to permit the brushes to be placed over the

commutator. Then push the commutator end frame and

the armature back against the field frame.

Lubrication

All bearings, wicks and oil reservoirs should be

saturated with SAE No. 20 oil. Place a light coat of

Fig. 7 - Checking Pinion Clearance Circuit.

lubricant Delco Remy No. 1960954 on the washer

located on the shaft between the armature and shift

lever housing.

10-8-16