TM 5-3895-359-14&P

Flywheel Ring Gears

The starting motor drive pinion and the engine flywheel

ring gear must be matched to provide positive

engagement and to avoid clashing of the gear teeth.

Flywheel ring gears with no chamfer are used with

starting motors equipped with an overrunning clutch

drive.

Remove Starting Motor

Failure of the starting motor to crank the engine at

normal cranking speed may be due to a defective

battery, worn battery cables, poor connections in the

cranking circuit, defective engine starting switch, low

temperature, condition of the engine or a defective

starting motor.

If the engine, battery and cranking circuit are in good

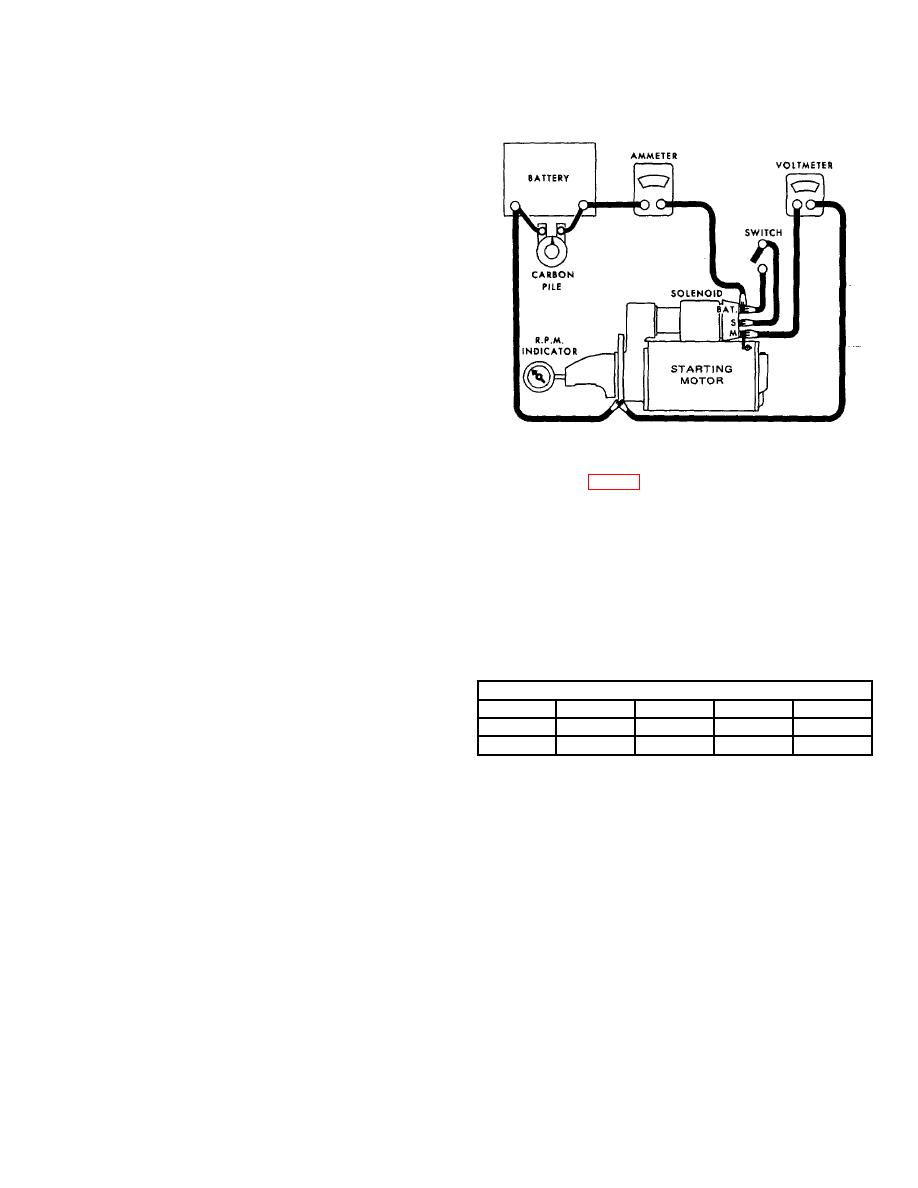

Fig. 3 - No-Load Test Circuit.

condition, remove the starting motor as follows:

No-Load Test (Fig. 3)

1. Remove the ground strap or cable from the battery or

the cable from the starting motor solenoid. Tape the

Connect a voltmeter from the motor terminal to the

end of the cable to prevent discharging the battery from

motor frame, and use an r.p.m. indicator to measure

a direct short.

armature speed. Connect the motor and an ammeter in

series with a fully charged battery of the specified

2. Disconnect the starting motor cables and solenoid

voltage, and a switch in the open position from the

wiring.

solenoid battery terminal to the solenoid switch terminal.

Close the switch and compare the r.p.m., current, and

NOTE: Tag each lead to ensure correct connections

voltage reading with the specifications in the NO LOAD

when the starting motor is reinstalled.

TEST TABLE below.

3. Support the motor and remove the three bolts and

NO LOAD TEST

lock washers which secure it to the flywheel housing.

Min

Max

Min

Max

Volts

Amps.

Amps.

RPM

RPM

Then pull the motor forward to remove it from the

10

90

150

3000

7600

flywheel housing.

It is not necessary to obtain the exact voltage specified

in the table as an accurate interpretation can be made

TROUBLESHOOTING

by recognizing that if the voltage is slightly higher the

r.p.m. will be proportionately higher, with the current

With the starting motor removed from the engine, the

remaining essentially unchanged. However, if the exact

armature should be checked for freedom of rotation by

voltage is desired, a carbon pile connected across the

prying the pinion with a screwdriver. Tight bearings, a

battery can be used to reduce the voltage to the

bent armature shaft, or a loose pole shoe screw will

specified value. If more than one 12-volt battery is

cause the armature to not turn freely. If the armature

used, connect the carbon pile to only one of the 12-volt

does not turn freely the motor should be disassembled

batteries. Make disconnections only with the switch

immediately. However, if the armature does rotate

open. Interpret the test results as follows:

freely, the motor should be given a no-load test before

disassembly.

10-8-13