TM 5-3895-359-14&P

will turn at crankshaft speed. However, as the blower

Gear train noise is usually an indication of excessive

drive gear has only about half as many teeth as the

gear lash, scoring, pitting or excessive bearing wear.

camshaft or balance shaft gear, it turns at approximately

Therefore, when noise develops in a gear train, the

twice the speed of the crankshaft.

flywheel housing should be removed and the gear train

and its bearings inspected. .A rattling noise usually

indicates excessive gear lash whereas a whining noise

is a result of too little gear lash.

Lubrication

Excessive wear and scoring may result from abrasive

The gear train is lubricated by overflow oil from the ,

substances or foreign material in the oil, introduced in

camshaft and balance shaft pockets spilling into the

the engine by such means as removal of the valve

gear train compartment. A certain amount of oil also

rocker cover without first cleaning away the dirt.

spills into the gear train compartment from the camshaft

and balance shaft end bearings and the idler gear

The backlash between the various mating gears in the

bearing. The blower drive gear bearing is lubricated

current 19 helix steel gear train is from .003 " to .008 "

through an external pipe leading from the main cylinder

with new parts and .010 " with used parts.

block oil gallery to the gear hub bearing support. The

idler gear bearing is pressure lubricated by oil passages

Since the camshaft and balance shaft gears each have

in the idler gear hub which connect to the oil gallery in

the same number of teeth as the crankshaft gear, they

the cylinder block.

ENGINE TIMING

1. Clean and remove the valve rocker cover.

The correct relationship between the crankshaft and

camshaft must be maintained to properly control fuel

injection, the opening and closing of the exhaust valves

2. Select any cylinder for the timing check -- it is

and engine balance.

suggested that a cylinder adjacent to one of the valve

rocker cover bolt or stud holes be chosen since the stud

or bolt may be used to mount a dial indicator.

The crankshaft timing gear can be mounted in only one

position since one attaching bolt hole is offset. The

camshaft gear can also be mounted in only one position

3. Remove the injector as outlined on Page 10-3-6.

due to the location of the keyway relative to the cams.

Therefore, when the engine is properly timed, the timing

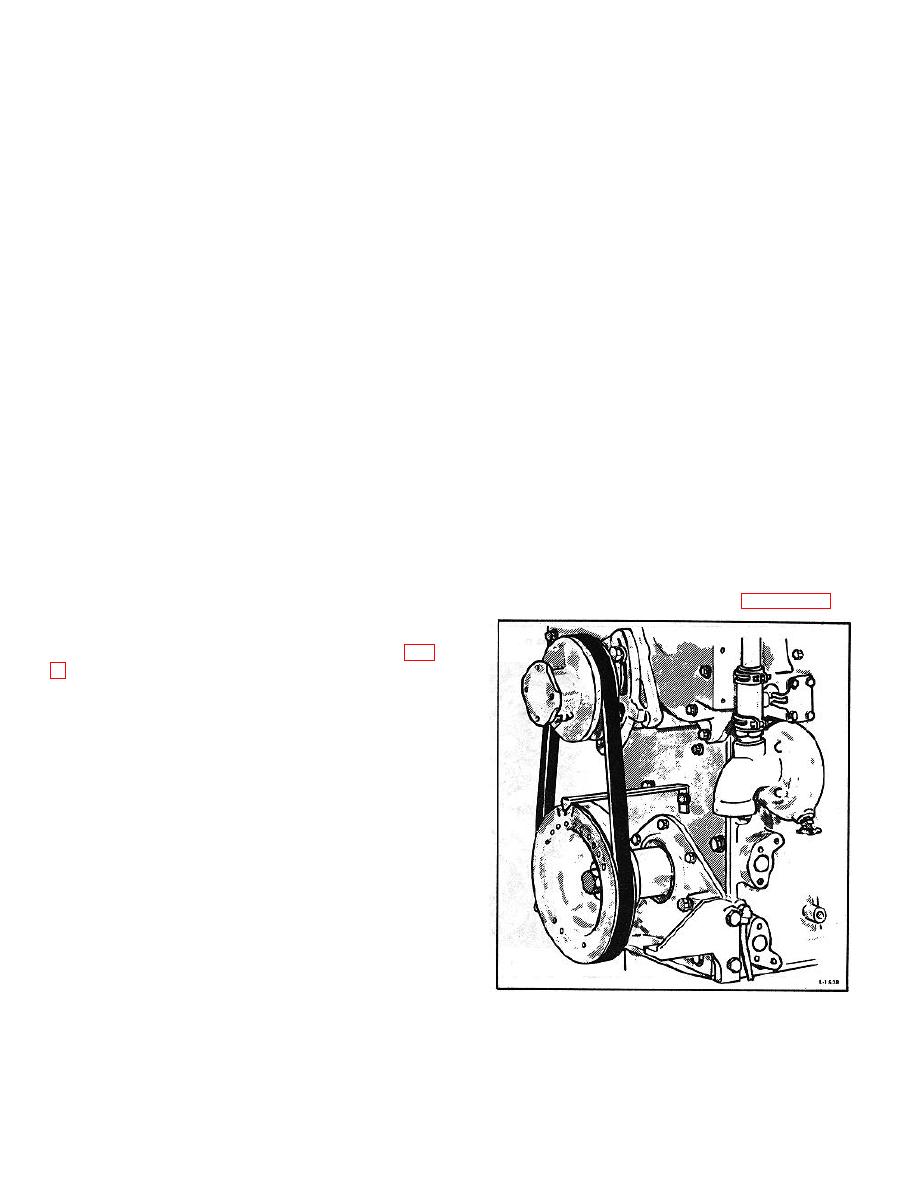

marks on the various gears will match as shown in Fig.

An engine which is out of time may result in pre-ignition,

uneven running and a loss of power.

When an engine is suspected of being out of time due to

an improperly assembled gear train, a quick check can

be made without having to remove the flywheel and

flywheel housing by following the procedure outlined

below.

Check Engine Timing

Access to the vibration damper or crankshaft pulley, to

mark the top-dead-center position of the selected piston,

and to the front end of the crankshaft or flywheel for

turning the crankshaft is necessary when performing the

timing check. Then proceed as follows:

Fig. 2. Pointer Installation for Marking Top-Dead-

Center

10-2-104