TM 5-3895-359-14&P

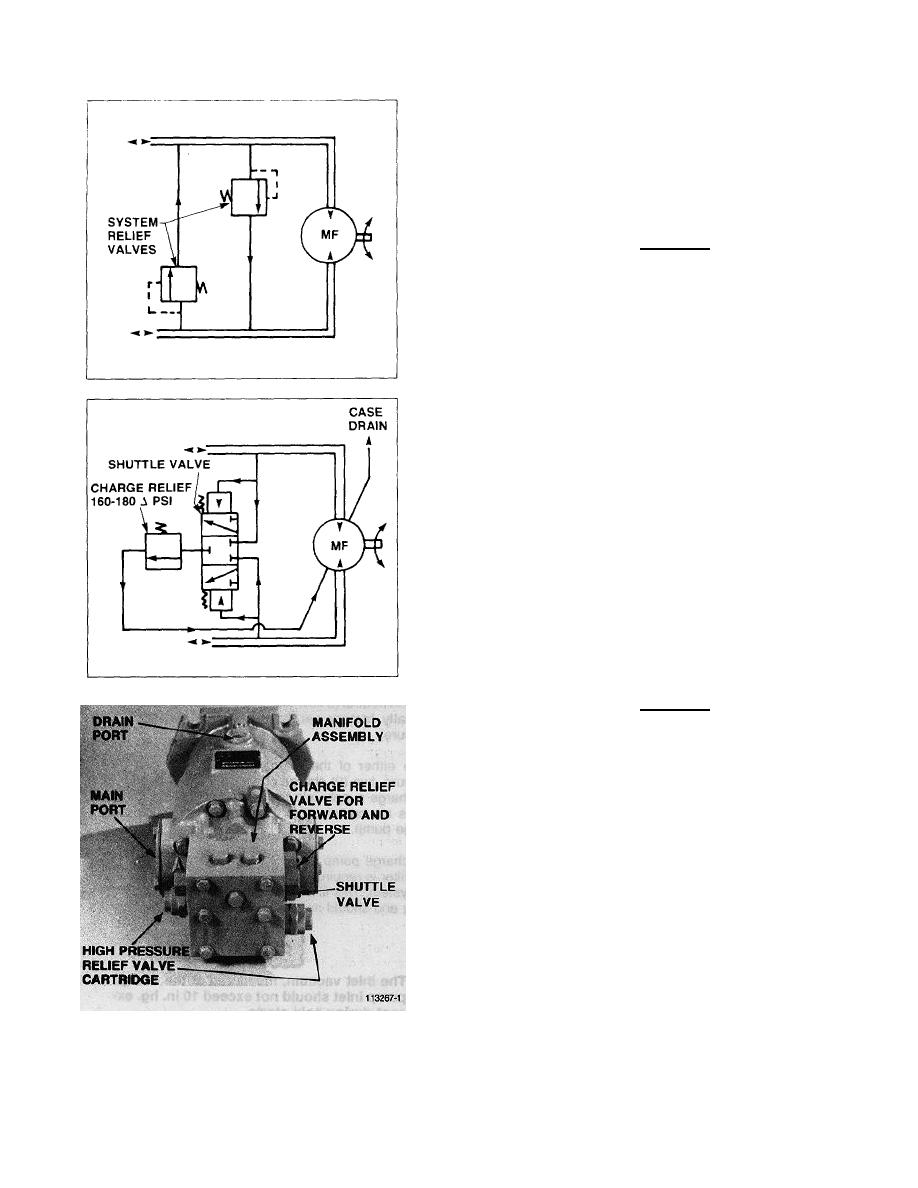

System Relief Valves

Two (2) System Relief Valves are provided for overload

protection and are located in the Manifold Assembly

mounted on the motor. These relief valves are factory

set and are of the pilot operated, cartridge type.

Changing the setting of these relief valves can be

accomplished by installing cartridges with the desired

setting. The first two (2) digits of the pressure setting

are stamped on the end of the relief valve cartridge.

CAUTION

The relief valves are factory set and

should not be tampered with except

to replace the entire cartridge.

Cooling Circuit

A Shuttle Valve and a second Charge Relief Valve are

included in the Manifold Assembly. The Shuttle Valve

provides a circuit between the low pressure hydraulic

line of the closed circuit to the second Charge Relief

Valve. This Charge Relief Valve is set at a lower

pressure (160-180 A PSI) than the relief valve located in

the Charge Pump. This Charge Relief Valve limits

Charge Pressure when the pump is in forward or reverse

(swashplate stroked out of neutral).

This system provides a means of removing hot fluid

from the main closed circuit so that cooler fluid entering

from the charge pump can be used to help reduce heat

build-up.

The Shuttle Valve is spring centered to the closed

position so that during the transition of reversing

pressures in the main hydraulic lines, no high pressure

fluid is lost from the closed circuit.

Charge Pressure

When the pump is in neutral (0 swashplate angle) the

Charge Pressure should be at 190-210 ∆PSI (above

case pressure). When the pump is in forward or reverse

(other than 0 swashplate angle) the Charge Pressure

should be at 160-180 ∆PSI (above case pressure).

CAUTION

Charge Pressure must not be less

than 160 ∆PSI for satisfactory

operation.

REMOVAL AND INSTALLATION

PUMP REPLACEMENT

1.

Remove dust shield from underside of front main

frame.

2.

Place a large oil drain pan under pump area.

3.

Remove the two universal joint U-bolts that attach

the drive line to the pump yoke.

4.

Remove and cap the pump suction line.

5.

Remove and cap the two case drive lines.

6.

Remove and cap the two high pressure hoses.

7.

Disconnect travel control cable and neutral start

switch wires from pump.

8.

Place lifting sling around the pump.

9.

Remove the pump mounting bolts and lower

pump out of mixer frame.

6-8