TM 5-3895-359-14&P

HYDRAULIC SUPPORT SYSTEM

The Sundstrand hydrostatic transmission is easy to

install, requiring no adjustments and few auxiliary

components. It has its own hydraulic support system

which is discussed in this section.

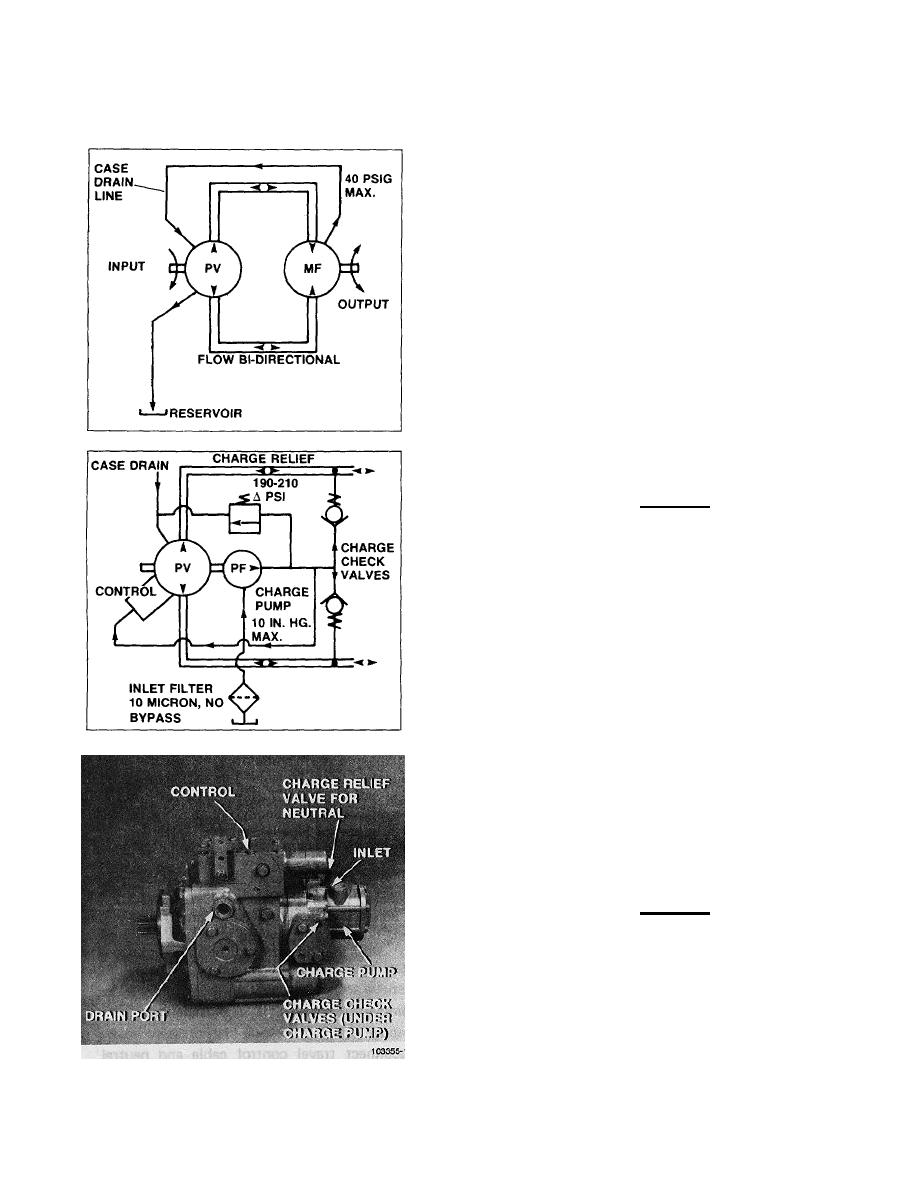

Basic Closed Circuit

The main ports of the pump are connected by hydraulic

lines to the main ports of the motor. Fluid flows, in

either direction, from the pump to the motor then back to

the pump in this closed circuit. Either of the hydraulic

lines can be under high pressure. The position of the

swashplate determines which line is high pressure as

well as the direction of fluid flow.

Case Drain

The pump and motor require case drain lines to remove

hot fluid from the system. The motor should be drained

from its topmost drain port to insure the case remains

full of fluid. The motor case drain is then connected to

the lower drain port on the pump housing and out the

upper port.

CAUTION

Case pressure should not exceed 40 PSIG.

Charge System and Inlet Filter

A fixed displacement (gear type) charge pump is

mounted on the variable displacement pump and driven

off the main pump shaft. The charge pump supplies

cool fluid to the system, keeps the system charged and

supplies fluid to operate the control system. Charge

pressure, with the pump in neutral (O flow), is limited by

a relief valve which is normally factory set for 190-210

APSI (above case pressure).

Since either of the main hydraulic lines can be high

pressure, two (2) charge check valves are used to direct

the charge supply into the low pressure line. The check

valves are contained in the pump end cap beneath the

charge pump.

The charge pump draws the fluid from the reservoir. An

inlet filter is required to insure that only clean fluid

enters the system. This filter should have a 10 micron

(nominal) rating and should not have a bypass.

CAUTION

The inlet vacuum, measured at the

charge pump inlet should not exceed

10 in. hg. except during cold starts.

6-7