TM 5-3895-359-14&P

1.

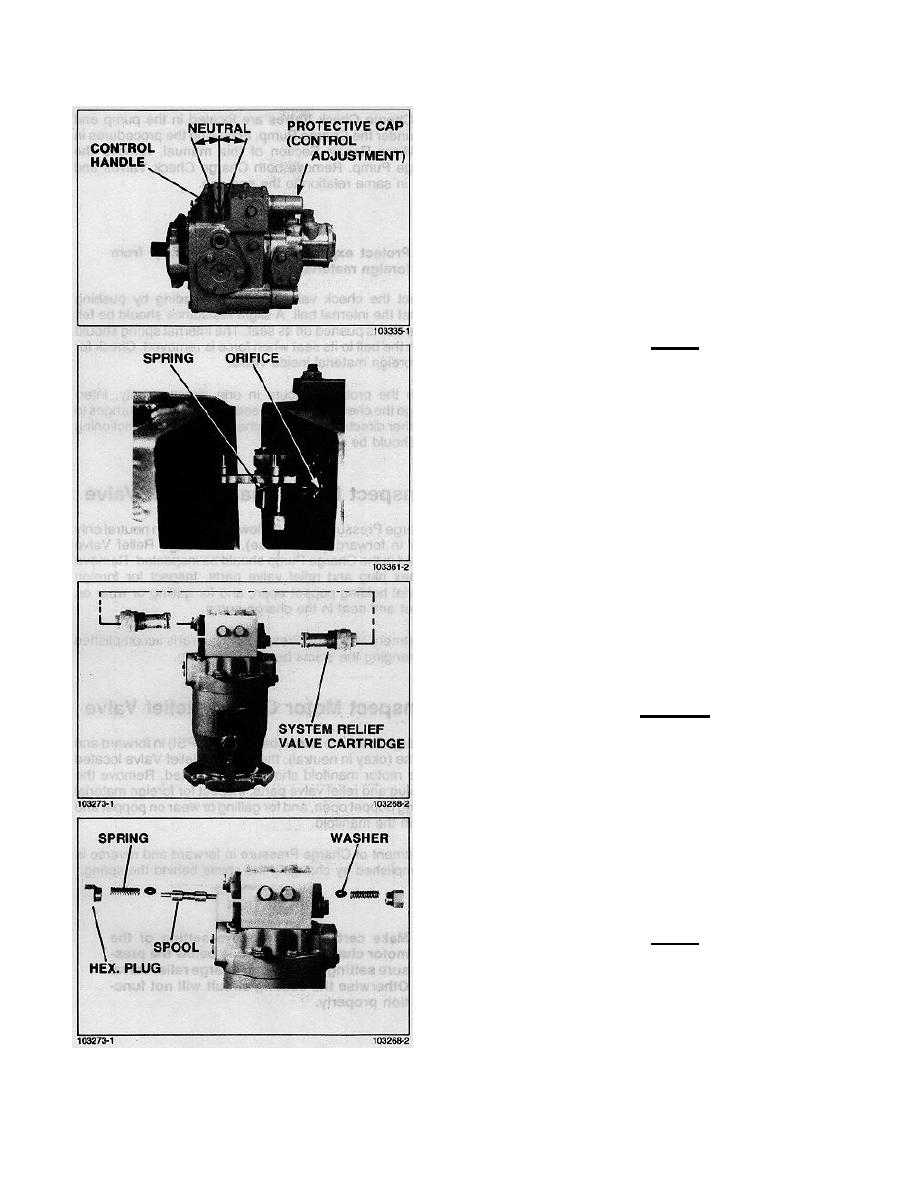

Inspect Manual Displacement Control

Disconnect the external control linkage from the control

handle and check for neutral operating with control

handle. Releasing control handle should allow the pump

to return to neutral. If operation is satisfactory with

external control linkage disconnected, the problem is not

in the hydrostatic transmission.

If operation is not satisfactory with external control

linkage disconnected from control handle, the control

may be misadjusted.

Adjustment procedures are

contained in this manual.

NOTE:

Before proceeding with control

adjustment the following inspection

is recommended.

Remove the cap screws holding the control in place,

and swing it away from housing and remove. Inspect

visible linkages, torsion spring, and O-rings. Inspect for

missing, plugged, or improper orifice.

2.

Inspect System Relief Valves

When the problem occurs in one direction only,

interchange the relief valve cartridges to see if the

problem changes to the other direction. If so, one relief

valve cartridge is either malfunctioning or does not have

the proper setting. The first two (2) digits of the

pressure setting are stamped on the end of the

cartridge. Compare to machine specification.

CAUTION

The relief valves are factory set and

should not be disassembled further.

3.

Inspect Shuttle Valve

Remove the two (2) hex plugs and the shuttle valve

parts. Inspect for broken or damaged parts and proper

orientation. Washers must go between spool and

springs. Inspect to see if spool moves smoothly in its

bore.

NOTE:

The spool and manifold are matched

and cannot be replaced separately.

6-13