TM 5-3895-359-14&P

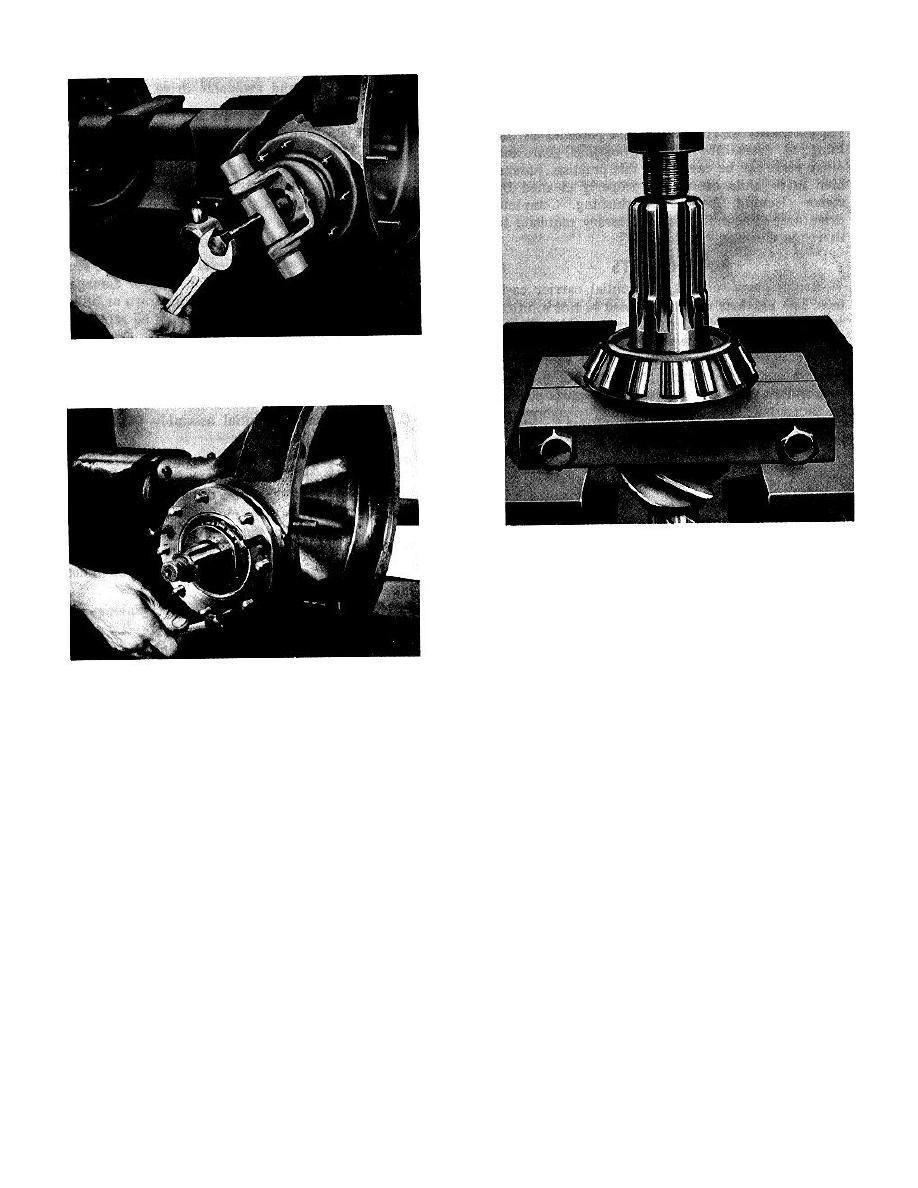

B. Remove outer bearing from cage.

C. Remove spacer or spacer combination

from pinion shaft.

B. Insert puller through yoke and remove.

C. Remove pinion bearing cover and oil seal

assembly.

D. Remove rear thrust bearing and radial

bearing with bearing puller if necessary to

replace.

E. Remove oil seal assembly from bearing

cover.

F. IF

NECESSARY

TO

REMOVE

DIFFERENTIAL BEARING CUPS, WIRE

THE SELECTIVE SPACERS WHICH

D. Remove pinion and cage assembly using

ARE BEHIND THE CUPS TO THEIR

puller screws in holes provided.

RESPECTIVE AXLE HALVES.

Driving pinion from inner end with a drift

will damage the bearing lock ring groove.

DISASSEMBLE PINION AND

CAGE ASSEMBLY

A. Tap shaft from cage with soft mallet or

press shaft from cage.

PREPARE FOR REASSEMBLY

Do NOT clean these parts in a hot solution tank or

CLEAN

with water and alkaline solutions such as sodium

Parts having ground and polished surfaces such as

hydroxide, orthosilicates or phosphates.

a suitable solvent such as SD-2 kerosene or diesel fuel

We do NOT recommend steam cleaning assembled

oil.

drive units after they have been removed from the

GASOLINE SHOULD BE AVOIDED.

housing. When this method of cleaning

WARNING

Potentially dangerous. Do not use

near open flame or heat.

5-13