TM 5-3895-359-14&P

Dieseling, is caused by the carbon and lead deposits in

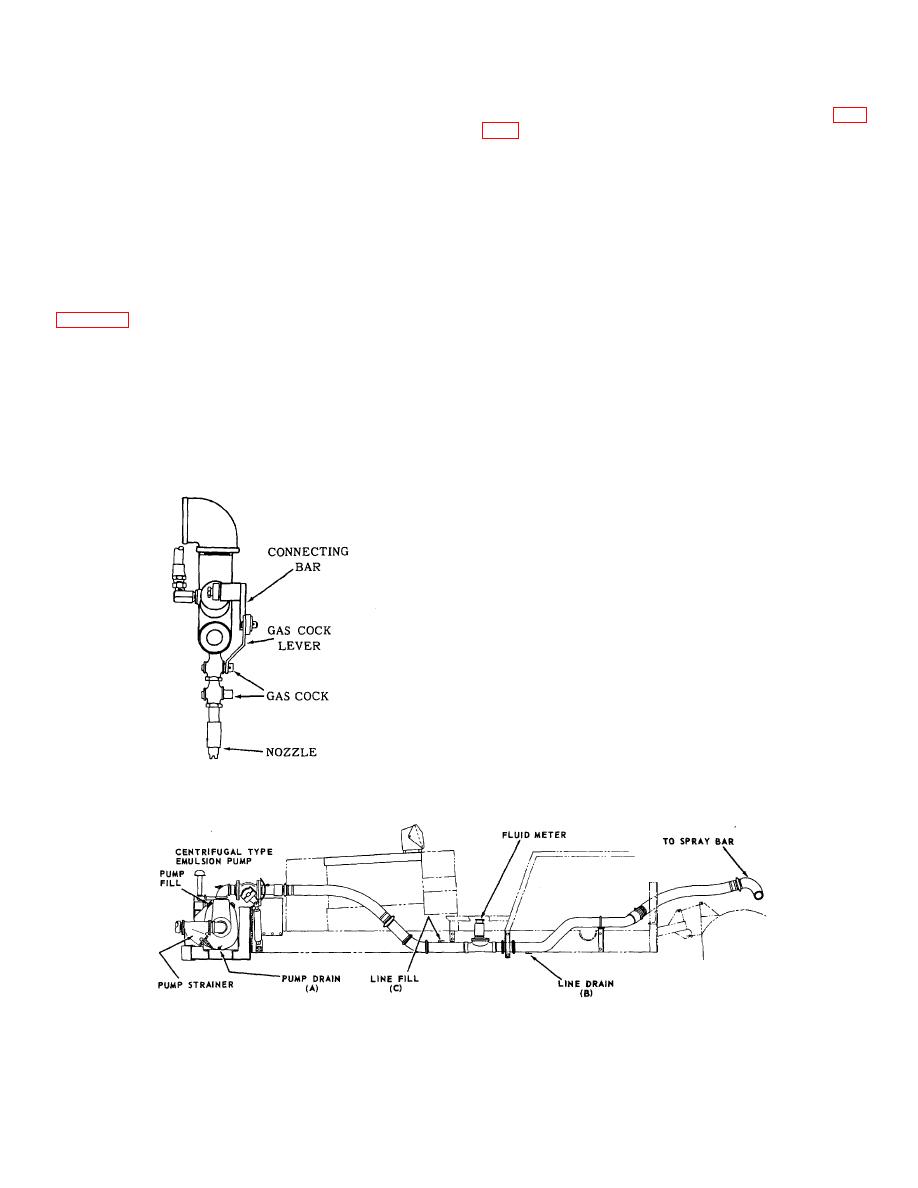

Cleaning Asphalt And Emulsion Fluid System (Fig.

the cylinder head being heated up to such an extent that

they continue to fire the engine and keep it running after

The system must be thoroughly flushed clean using fuel

the ignition has been shut off. By idling the engine, as

oil. A fuel oil tanker can be hooked up to the liquid

previously mentioned, the carbon and lead deposits cool

pump in a similar manner as for processing soil.

off, break up and will blow out thru the exhaust, If

engine has a tendency to diesel, by suddenly setting the

If pump body is not full, it must be primed with fuel oil

throttle wide open and at the same time shutting off the

first. Run pump engine at approximately half throttle.

ignition, the engine will stop.

All spray nozzles must be open. Open tailboard to its

extent. Raise hood and rotor to their extent. Lower

Turn ignition key (22) off after engine cooling period.

nozzles into hood. Rotate rotor in high. Centrifugal

force of the rotor plus the fuel oil will clean the rotor.

Operating Only A Portion Of The Spray Bar Nozzles

CAUTION: MAKE SURE NO PERSONNEL ARE

The spray bar nozzle assembly is equipped with two /2"

BEHIND THE MACHINE AS THEY MAY BE HIT

"gas" cocks. The upper "gas" cock being linked to the

WITH FLYING MATERIAL.

connecting bar with a valve lever. The lower "gas" cock

may be closed with a wrench, thus shutting off the liquid

Flush system until clean oil appears at the nozzles.

flow thru that particular nozzle.

The system is equipped with a strainer at the intake side

When flushing out the liquid system at the end of

of the pump to retain any solids from entering the fluid

operation, all nozzles must be flushed out by opening

system which could cause damage and possible failure

the "gas" cocks previously closed.

of the meter or pump.

Frequent inspection and cleaning of the strainer must be

made using fuel oil or solvent, SD-2.

WARNING

Solvent SD-2 is potentially dangerous. Do not

use near open flame or heat.

The fuel oil may be drained from the fluid system by

opening the pump drain (A) and line drain (B). It is

recommended that fuel oil be left in the system until the

following day's operation.

Each line is equipped with a line fill plug (C) that may be

removed and fuel oil added to the lower line system as a

protection to the meter in case of an emergency.

When the fluid system is not going to be used for some

time, remove the suction line and cap the pump intake.

Figure 1-13. Spray bar Nozzle Assembly

Fill

entire

system

with

fuel

oil.

Figure 1-14. Emulsion Fluid System

22