TM 5-3895-359-14&P

If the pump has been pumping liquid containing a

determine optimum forward travel speed. For example,

considerable amount of solids, it is advisable to flush the

select a speed of 112 feet per minute. This would

solids out of the body before refilling with liquid. In

indicate from the application chart, Table 1-3, a

freezing weather, the pump should be primed with warm

quadrant setting for the metering valve of seven for

water if possible. Always drain pump after it has been

water or eight for emulsified asphalt at 112 fpm. The

operating in freezing temperatures.

flow rate as indicated on the application chart will be 400

gallons per minute which will be read on the gal./min.

Attach suction hose to the tank truck. Suction hose

gauge. The gallons per lineal foot will be 3.57 as

connections must be tight with no leaks. Air being

indicated in column six. With the figure of 3.57 gallons

drawn into the suction line affects the pumping capacity.

per lineal foot and knowing the tank truck capacity, it

Make sure outlet valve on tank truck is open after

can be determined how many lineal feet will be covered

connecting the hose.

with the capacity of the tank truck. A 5,000 gallon tank

truck will cover approximately 1,400 lineal feet of soil to

Start machine engine and run at 2,000 rpm when

be processed.

processing the soil.

The proportioning gauge will indicate whether or not the

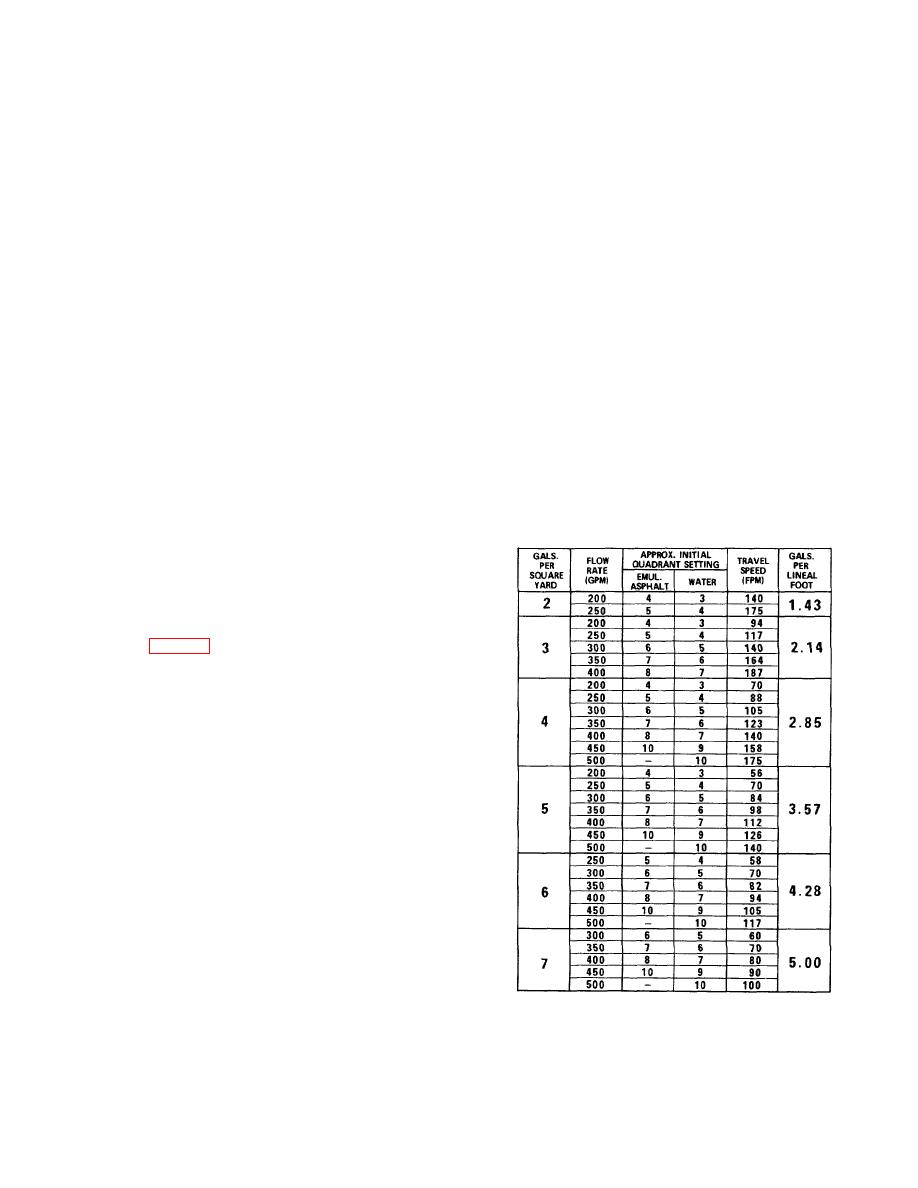

Using the application chart, Table 1-3, as an initial start

liquid being pumped is in relationship to the feet per

(per example in paragraph 2) turn knob on gallons per

minute travel speed. When the needle varies to the left,

square yard gauge to desired setting.

"lean," this indicates an adjustment of more liquid is

needed and the metering valve must be opened by

Open metering valve by actuating the metering valve

actuating the metering valve control lever.

control lever to indicated setting on application chart.

A needle variance to the right, "rich," indicates too much

Start pump engine and run at governed engine rpm.

liquid is passing in relationship to the feet per minute

travel speed and a closing adjustment to the metering

valve must be made.

It is always better to vary the liquid volume so that a

constant forward speed may be maintained by the tank

truck Pulvi-Mixer train.

2. Operation (Fig. 1-9)

The following V.P.I.

fluid handling suggested

instructions are to be used with the preceding

instructions on "Forward and Reverse Travel" and the

"Material Processing" instructions.

Attach suction hose to the liquid pump intake.

Swing the boom around to the front of the machine and

thread hose through the spring loop and attach end of

spring to the boom hook.

CAUTION: Do not operate pump without

liquid in the pump body as operating pump

dry will result in damage to the seal.

The liquid pump must be primed before starting

operations.

Remove priming plug from the pump and use liquid

from the tank truck to fill pump body. Replace plug.

(CAUTION: DO NOT ATTEMPT TO FILL THE PUMP

BODY WITH THE PUMP ENGINE RUNNING.) The

pump is now ready for operation. The liquid used to

Table 1-3. Pulvi-Mixer Reference Application Chart.

prime the pump should be as free of solids as possible.

20