TM 5-3895-369-14

Compressed air used for cleaning purposes must not exceed 30 psi (207 kPa). Use only with effective

chip guarding and personal protective equipment (goggles/shield, gloves, etc).

(2)

Dry all parts, except bearing cups, with compressed air. Let bearings air dry.

(3)

Check all parts for damage.

(4) Replace damaged parts.

c.

Assembly.

NOTE

This procedure is the same for both ends of

the clutch drive shaft.

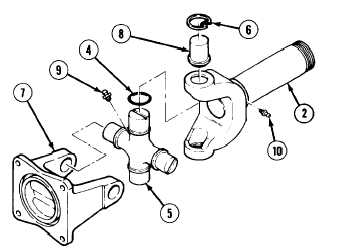

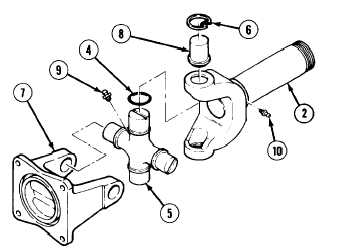

(1)

Install grease fitting (10) in slip yoke (2)

(2)

Install grease fitting (9) and position four

seals (4) on universal joint (5).

(3)

Position universal joint (5), flange yoke (7),

and slip yoke (2).

CAUTION.GPH;12p10;6 P10;TIFF

Be careful when installing bearing cups.

Needle bearings may fall out and become

damaged or lost.

(4)

Apply grease in insides of four bearing cups (8) and install slip yoke (2) and flange yoke (7) over ends of

universal joint.

(5)

Install four clips (6) and slide grease seals (4) into place.

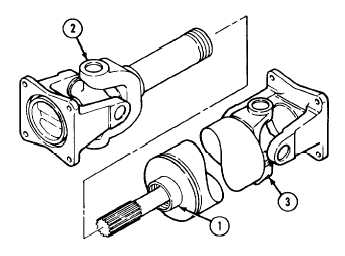

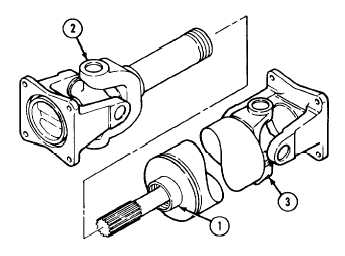

(6)

Align matchmarks and install slip yoke (2) on drive shaft (3).

(7) Install seal (3).

NOTE

Follow-on Maintenance:

Install drive shaft (para 4-102)

Lubricate drive shaft (figure 3-1).

END OF TASK

5-363