TM 5-3895-369-14

5-68. DIFFERENTIAL ASSEMBLY REPLACEMENT.

This task covers:

b. Cleaning/Inspection

c. Assembly

a. Removal

INITIAL SETUP

Personnel Required

Tools

MOS62B, Construction equipment repairer (2)

Tool kit, general mechanic's: equipment

maintenance and repair

Equipment Condition

TM or Para

Condition Description

Lifting device (capacity 200 lb [91 kg])

Rear axle removed.

Two-speed range box

Wrench, torque

removed from rear axle.

Wheel ends and axle

Suitable container (capacity 5 gal. [19 liters])

shafts removed from

rear axle.

Materials/Parts

Adhesive-sealant, silicone (item 1, appendix E)

Cloth, lint-free (item 12, appendix E)

Compound, retaining (item 18, appendix E)

Oil, lubricating, gear (item 31, appendix E)

Solvent, drycleaning (item 54, appendix E)

a.

Removal.

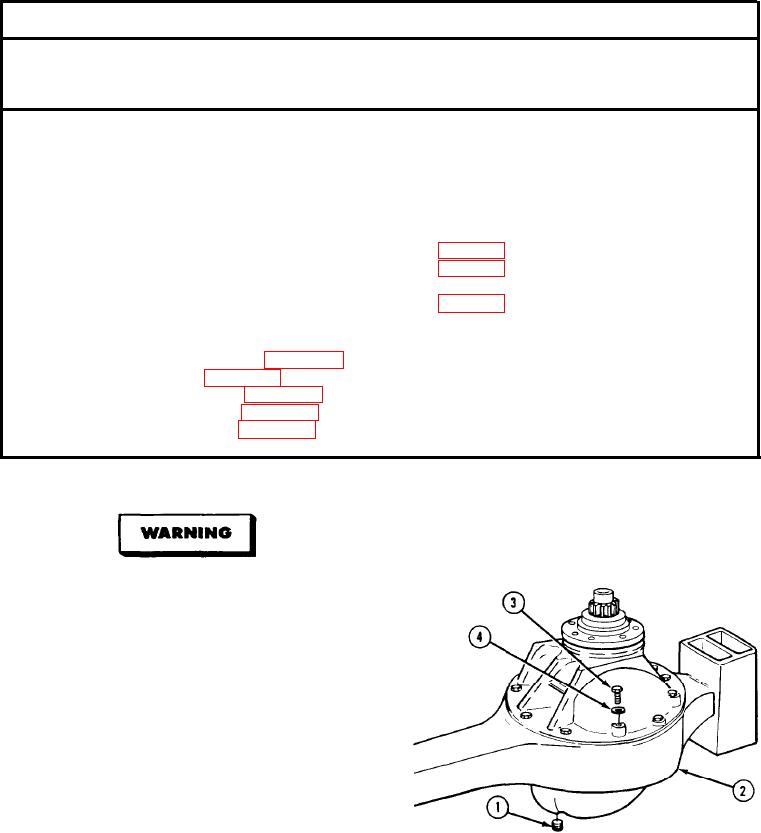

Spilled oil is slippery. Clean up spilled

oil immediately or injury to personnel

may result.

NOTE

Place suitable container with a 5 gallon

(19 liters) capacity under axle housing to

catch drained oil.

(1) Remove plug (1) and drain gear oil from

axle housing (2).

(2) Remove 10 screws (3) and washers (4).

5-392