TM 5-3895-369-14

NOTE

If used, mounting bracket must be

removed for the following steps.

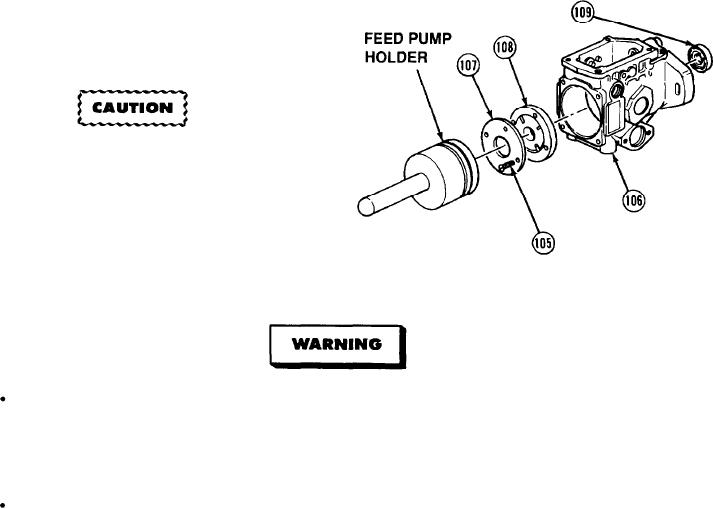

(43) Remove two screws (105).

(44) Install feed pump holder and tilt fuel pump

housing (106) up.

Ensure not to drop blades in liner or

damage to feed pump will result.

(45) Remove support ring (107) and feed

pump (108).

(46) Remove and discard oil seal (109) from fuel

pump housing (106).

c.

Cleaning/Inspection.

Drycleaning solvent (P-D-680) is TOXIC and flammable. Wear protective goggles and gloves; use

only in well-ventilated area; avoid contact with skin, eyes, and clothes, and do not breathe vapors.

Keep away from heat or flame. Never smoke when using solvent; the flashpoint for type I

drycleaning solvent is 100F (38C) and for type II is 138F (50C). Failure to do so may result in

injury or death to personnel.

If personnel become dizzy while using cleaning solvent, immediately get fresh air and medical help.

If solvent contacts skin or clothes, flush with cold water. If solvent contacts eyes, immediately flush

eyes with water and get immediate medical attention.

(1) Wash all metal parts with drycleaning solvent.

(2) Wipe off all parts with a lint free cloth.

(3) Inspect fuel pump housing for nicks, cracks, and burns.

(4) Inspect adapter and solenoid valve sealing surfaces for wear and orifices for blockage.

(5) Inspect spur gear teeth for pitting and cracks.

(6) Inspect governor lever assembly ball pin movement and lever action. If action has catches, replace

governor lever assembly.

(7) Inspect roller bearings for wear and catches in rotation.

5-249