TM 5-3895-369-14

NOTE

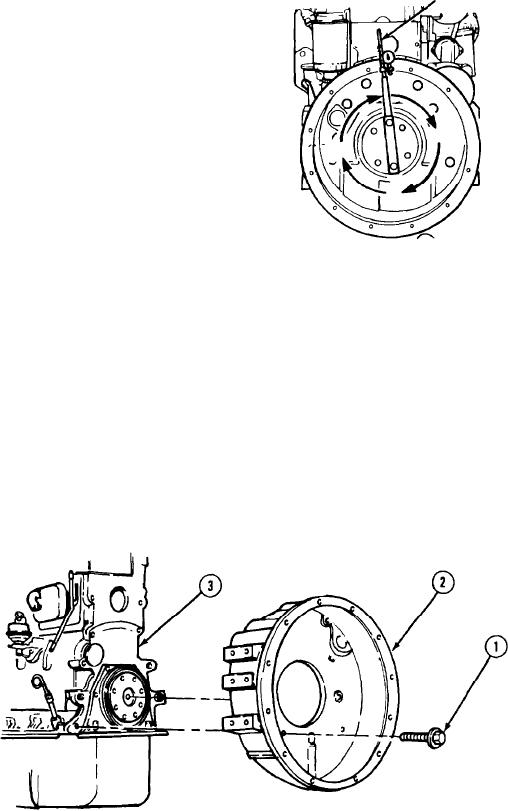

Perform step (2) when troubleshooting a

DIAL INDICATOR

transmission vibration problem or

checking flywheel housing face alignment.

(2) Determine total indicator reading (TIR)

as follows:

(a) Mount dial indicator as shown.

(b) Adjust dial at 12 o'clock position until

it reads zero. Rotate dial once to 12

o'clock position. Dial must read zero

to get correct measurements.

(c) Slowly rotate dial to 3 o'clock, 6

D-1327-W

o'clock, 9 o'clock, and 12 o'clock

positions, recording measurements for

each position.

(d) Raise rear of crankshaft to its upper limit with dial at 12 o'clock position. Record measurement.

This measurement is called bearing clearance.

(e) Determine bearing clearance adjustment by subtracting 1/2 of bearing clearance from 6 o'clock

position recorded in step (2 (c)).

Add vertical measurements (12 o'clock position and bearing clearance adjustment).

(f)

(g) Add horizontal measurements (3 o'clock and 9 o'clock positions).

(h) Add totals from vertical and horizontal measurements to get total indicator reading (TIR).

Maximum allowable TIR is 0.008 in. (0.20 mm). If measurement is greater than maximum allowable

(i)

TIR, replace flywheel housing.

(3) Remove eight screws (1) and flywheel housing (2) from engine (3).

5-157