TM 5-3895-369-14

Do not apply grease on outer diameter of

bearing halves or damage may result to

bearing halves, related bearing caps, and

crankshaft.

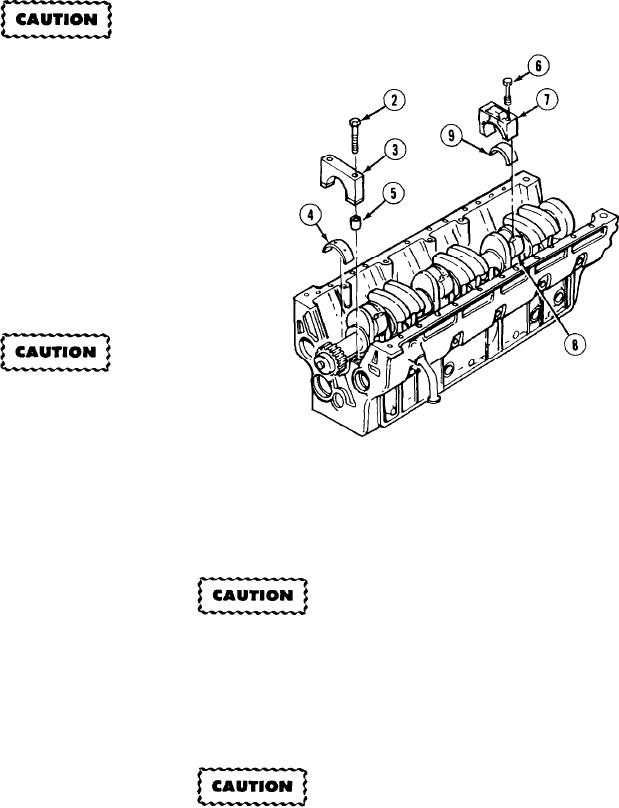

(10) Lubricate six top rod bearing halves (9) and

seven top bearing halves (4) on convex side

only with general purpose grease.

(11) Install six top rod bearing halves (9) in six

rod caps (7).

(12) Lubricate threads of 12 screws (6) and

underside of six rod caps (7) with engine oil.

Rod bearing caps and connecting rods have

numbers located on one side. Numbers

must be alined and match. Failure to do so

will result in damage to crankshaft and

connecting rod assemblies.

(13) Install six rod caps (7) on six connecting rods (8) with 12 screws (6). Do not tighten screws.

(14) If removed, install 14 ring dowels (5) in seven bearing caps (3).

Do not apply grease on outer diameter of bearing halves or damage may result to bearing halves, related

bearing caps, and crankshaft.

(15) Lubricate seven top bearing halves (4) with general purpose grease.

(16) Lubricate 14 screws (2) and seven bearing caps (3) with engine oil.

Bearing caps have numbers located on top near ring dowels. Numbers must face oil cooler side of engine

beginning with number 1 at front of engine (fan side). Failure to properly install could cause damage to

engine.

(17) Install seven bearing caps (3) with 14 screws (2).

5-143