TM 5-3895-359-14&P

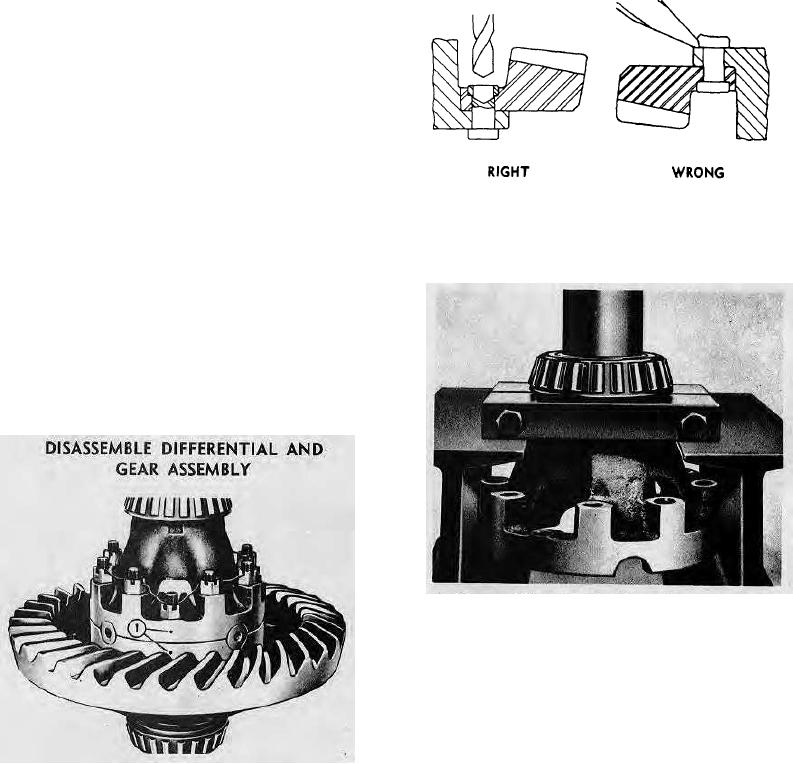

A. If original identification marks are not clear, mark

ROTOR DRIVE AXLE

differential case halves with a punch or chisel (as

shown in photograph above) before disassembling,

GENERAL

for correct alignment when reassembling.

The Rockwell-Standard Company Unit-Type Housing

B. Cut lock wire, remove bolts or cap screws and

separate case halves.

Drive Unit is a single-reduction drive of hypoid design.

C. Remove spider, pinions, side gears and thrust

The differential and gear assembly is mounted on

washers.

tapered roller bearings with the cups assembled in the

D. Remove rivets and separate gear and case if

case and cover halves of the housing. The straddle

required.

mounted pinion has two tapered roller bearings located

forward of the pinion teeth and a radial bearing at the

inner end.

REMOVE GEAR RIVETS

The pinion shaft is splined to accommodate the flange

and the bearing pre-load controlled by hardened and

ground spacers of the correct thickness between the

bearings. Bearings are retained in position by the

companion flange nut.

DISASSEMBLE AXLE

A. Before disassembling, place length of pipe or

suitable support, slightly smaller than axle shaft

splines, approximately two-thirds through axle from

the case side to prevent dropping the differential

assembly.

1. Carefully centerpunch rivets in center of head.

2. Use drill 1/32" smaller than body of rivet to drill

B.

Remove bolts, nuts and washers from case and

through head.

cover and remove cover half.

3. Press out rivets.

C. Remove differential and gear assembly.

D. Remove pipe.

DISASSEMBLE DRIVE UNIT

DISASSEMBLE DIFFERENTIAL AND GEAR

ASSEMBLY

E. Remove differential bearings with bearing puller if

necessary to replace.

REMOVE PINION AND CAGE ASSEMBLY

The differential and gear assembly must be

removed before the pinion and cage assembly can be

disassembled.

4-12