TM 5-3895-359-14&P

Air Inlet Restriction Excessive restriction of the air inlet

plug which is provided for that purpose. If no opening is

will affect the flow of air to the cylinders and result in

provided, drill an 11/32" hole in the exhaust manifold

poor combustion and lack of power. Consequently the

companion flange and tap the hole to accommodate a

restriction must be kept as low as possible considering

1/8" pipe plug.

the size and capacity of the air cleaner. An obstruction

in the air inlet system or dirty or damaged air cleaners

Check the readings obtained at various speeds (at no-

will result in a high blower inlet restriction.

load) with the Engine Operating Conditions on Page 10-

9-1.

Check the air inlet restriction with a water manometer

connected to a fitting in the air inlet ducting located 2"

Air Box Pressure

above the air inlet housing.

When practicability

prevents the insertion of a fitting at this point the

Proper air box pressure is required to maintain sufficient

manometer may be connected to the engine air inlet

air for combustion and scavenging of the burned gases.

housing. The restriction at this point should be checked

Low air box pressure is caused by a high air inlet

at a specific engine speed. Then the air cleaner and

restriction, damaged blower rotors, an air leak from the

ducting should be removed from the air inlet housing

air box (such as leaking end plate gaskets) or a clogged

and the engine again operated at the same speed while

blower air inlet screen. Lack of power or black or grey

noting the manometer reading.

exhaust smoke are indications of low air box pressure.

The difference between the two readings, with and

High air box pressure can be caused by partially

without the air cleaner and ducting, is the actual

plugged cylinder liner ports.

restriction caused by the air cleaner and ducting.

Check the air box pressure with a manometer connected

Check the normal air inlet vacuum at various speeds (at

to an air box drain tube.

no-load) and compare the results with the Engine

Operating Conditions on Page 10-9-1.

Check the readings obtained at various speeds with the

Engine Operating Conditions on Page 10-9-1.

PROPER USE OF MANOMETER

The U-tube manometer is a primary measuring device

Should one column of fluid travel further than the other

indicating pressure or vacuum by the difference in the

column, due to minor variations in the inside

height of two columns of fluid.

Connect the manometer to the source of pressure,

vacuum or differential pressure. When the pressure is

imposed, add the number of inches one column of fluid

travels up to the amount the other column travels down

to obtain the pressure (or vacuum) reading.

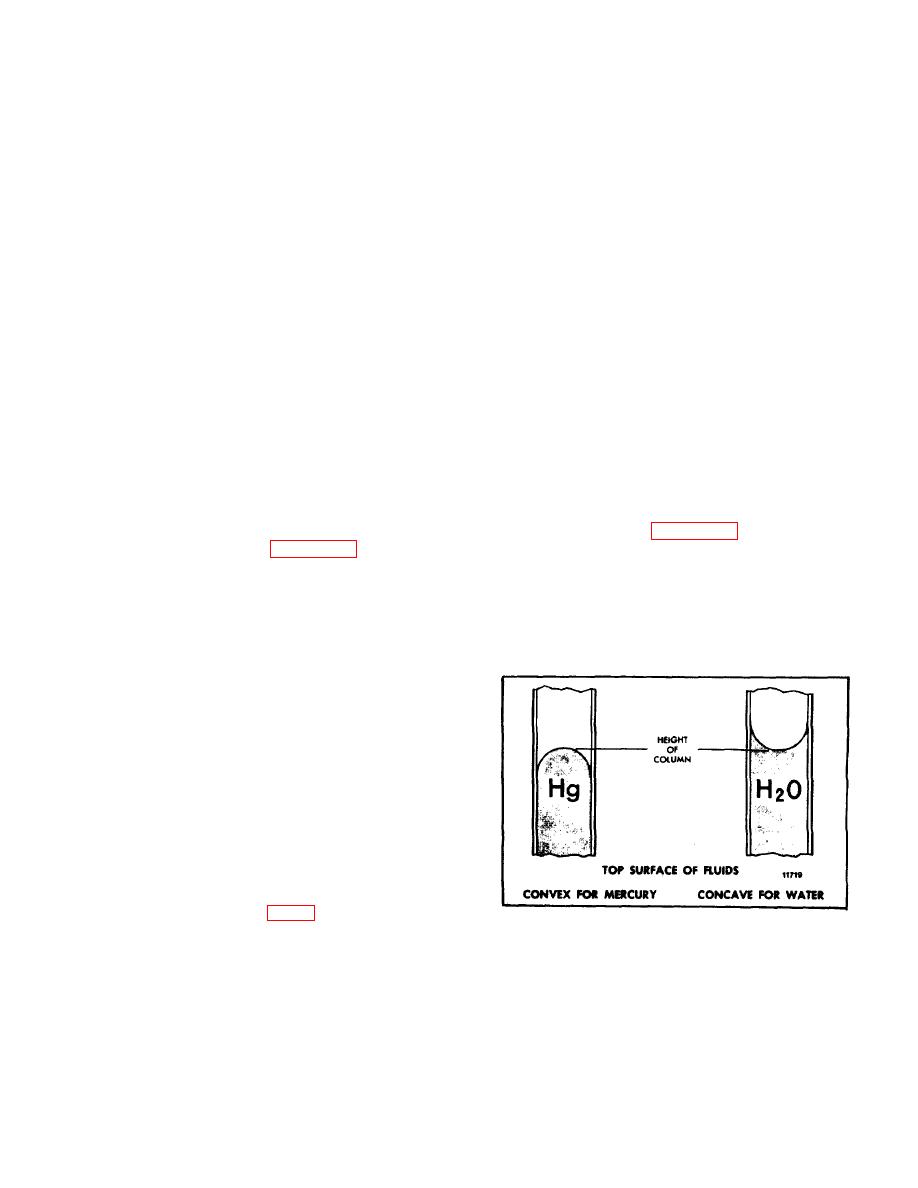

The height of a column of mercury is read differently

than that of a column of water. Mercury does not wet

the inside surface; therefore, the top of the column has

a convex meniscus (shape). Water wets the surface

and therefore has a concave meniscus. A mercury

column is read by sighting horizontally between the top

of the convex mercury surface (Fig. 4) and the scale. A

water manometer is read by sighting horizontally

Fig. 4 - Comparison of Column Height for Mercury

between the bottom of the concave water surface and

and Water Manometers

the scale.

10-11-12