TM 5-3895-359-14&P

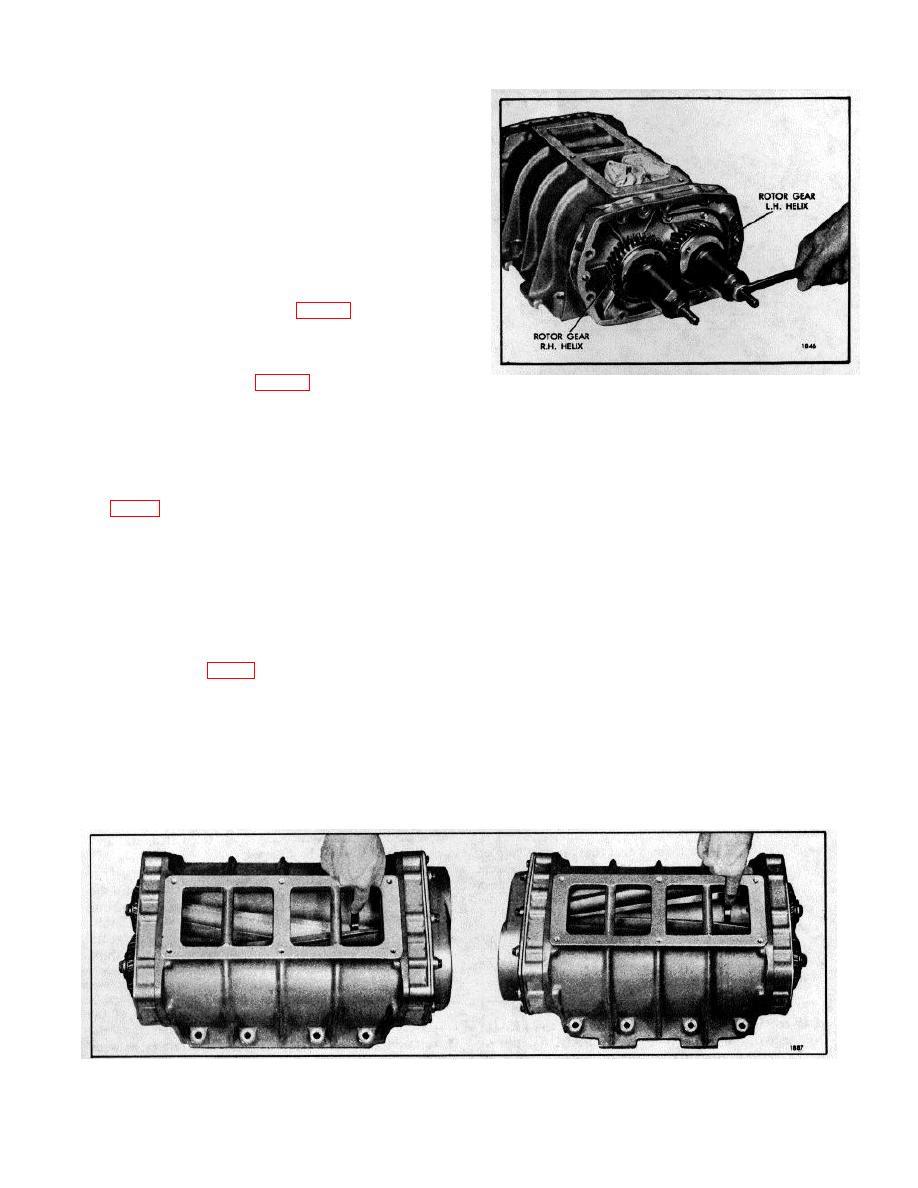

f. Start both rotor gears straight on the rotor shafts

with the right-hand helix gear on the right-hand

helix rotor and the left-hand helix gear on the

left-hand helix rotor, and the omitted serrations

in the gears in line with the omitted serrations on

the rotor shafts.

g. Thread an installer screw J 6270-8 in the end of

each rotor shaft until it bottoms. Place gear

installer J 6270-7 over the installer screw and

against the right-hand helix gear and gear

installer J 6270-6 over the installer screw and

against the left-hand helix gear. Then, thread a

nut on each installer screw (Fig. 15).

h. Place a clean folded cloth between the lobes of

the rotors, to prevent the rotors from turning.

Then, turn the nuts on the installer screws

clockwise as shown in Fig. 15 and draw the two

Fig. 15 - Installing Rotor Gears on Rotor Shafts for

gears into position at the same time, tight

Preliminary Check of Clearances using Tool J 6270-

against the shims and bearing inner races.

6, 7 and 8.

i. Remove the rotor timing gear installers from the

l. Bend one of the tangs of each lock washer over

rotor shafts.

against the head of the gear retaining bolt.

Remove the cloth from between the blower

j. Place a lock washer (16) and the gear retaining

rotors.

washer (19) on one of the gear retaining bolts

helix rotor shaft, and guide the lugs on the

Timing Blower Rotors

retaining washer in the slots in the gear hub.

After the blower rotors and timing gears are installed,

the blower rotors must be timed.

Bend one of the tangs on the lock washer over

into the slot of the retaining washer. Tighten the

The blower rotors, when properly positioned in the

gear retaining bolt to 55-65 lb-ft (75-88 Nm)

housing, run with a slight clearance between the lobes.

This clearance may be varied by moving one of the

k. Place a lock washer (16) and the fuel pump

helical gears in or out on the shaft relative to the other

drive coupling disc (18) on the remaining gear

gear.

retaining bolt (Fig. 7). Thread the bolt into the

left hand helix rotor shaft and guide the lugs on

If the right-hand helix gear is moved out, the right-hand

the disc in the slots in the gear hub. Then bend

helix rotor will turn counterclockwise when viewed from

one of the tangs on the lock washer over into

the gear end. If the left-hand helix gear is moved out,

the slot in the disc. Tighten the gear retaining

the left-hand helix rotor will turn clockwise when viewed

bolt to 55-65 lb-ft (75-88 Nm) torque.

from the gear end. This positioning of the gear, to

obtain the proper clearance between the rotor lobes, is

known as blower timing.

Fig. 16 - Measuring "CC" and "C" Clearances Between Blower Rotor Lobes.

10-4-17