TM 5-3895-359-14&P

10. Remove the bearings and the lip type oil seals from

the blower end plates as follows:

a. When performing a major overhaul, discard the

oil seals, otherwise inspect the oil seals. If the

seals are scored, or hard, new seals must be

installed. If necessary, remove the seals from

the end plates at the same time the individual

bearings are removed.

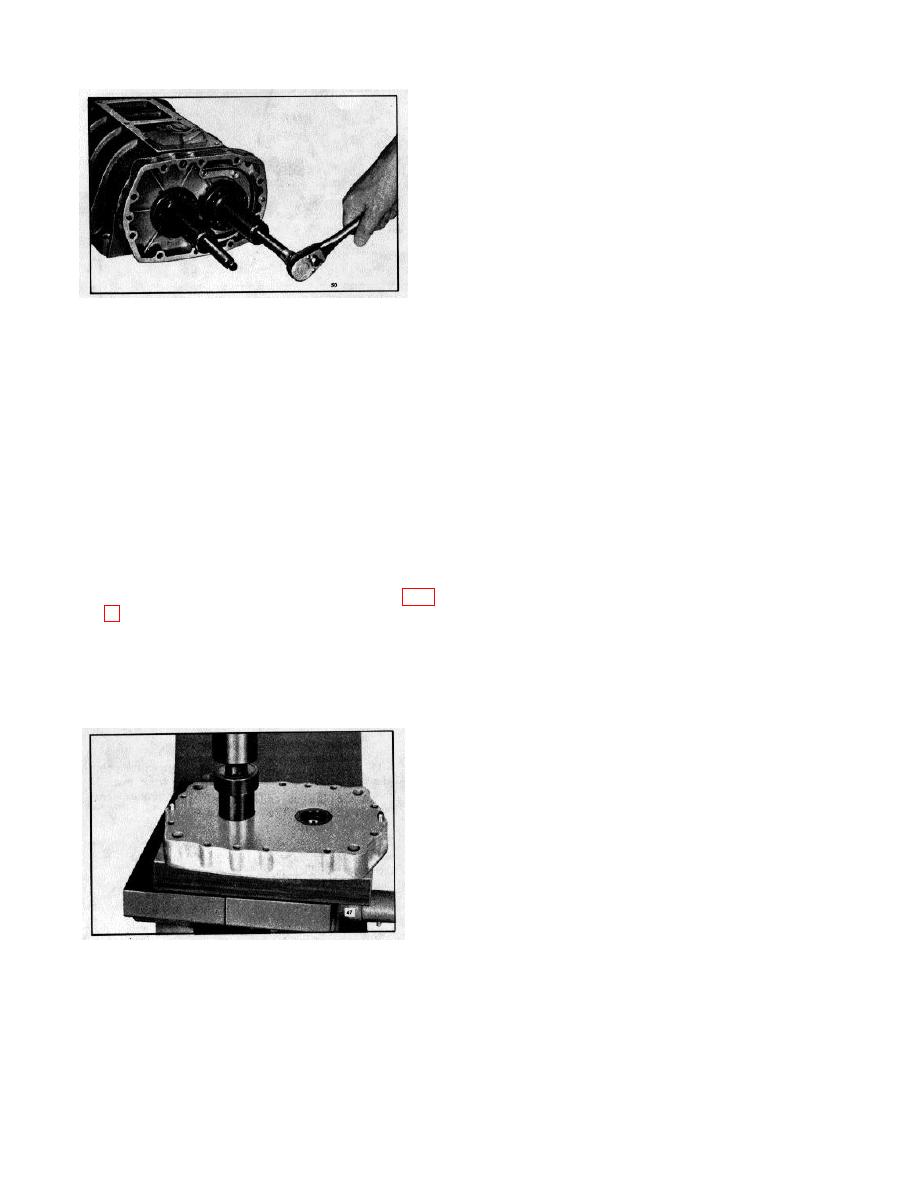

b. Support the outer face of the end plate on wood

blocks on the bed of an arbor press.

c. Place the long end of the oil seal remover and

Fig 5 - Removing Blower End Plate using Tool

installer J 6270-3 down through the oil seal and

Set J 6270-F

into the bearing, with the opposite end of the

c. Align the hole in each puller flange with the

remover under the ram of the press (Fig. 6).

tapped holes in the end plate and secure the

Then, press the bearing and oil seal out of the

pullers to the end plate with six 1/4"-20 x 1-1/4"

end plate. Discard the oil seal.

bolts.

d. Remove the remaining bearings and oil seals

from the end plates in the same manner.

CAUTION: Be sure that the 1/4"-20

Inspection

bolts are threaded all the way into

Wash all of the blower parts in clean fuel oil and dry

the tapped holes in the end plate to

them with compressed air.

provide maximum anchorage for the

pullers and to eliminate possible

Examine the bearings for any indications of corrosion or

damage to the end plate.

pitting. Lubricate each bearing with light engine oil.

Then, while holding the bearing inner race from turning,

d. Turn the two pullers screws uniformly clockwise

revolve the outer race slowly by hand and check for

and withdraw the end plate and bearings from

rough spots. .

the blower housing and rotors as shown in Fig.

The double-row ball bearings are pre-loaded and have

no end play. A new double-row bearing will seem to

have considerable resistance to motion when revolved

8. Remove the blower front end plate in the same

by hand.

manner as described in Step 7 above.

9. Withdraw the blower rotors from the housing.

NOTE: When a blower with lip type

oil seals is being reconditioned

oversize oil seals and oil seal

spacers are available in the blower

kit to replace the standard oil seals

where the blower rotor shafts are

grooved.

Inspect the blower rotor lobes, especially the sealing

ribs, for burrs and scoring. Rotors must be smooth for

efficient operation of the blower. If the rotors are slightly

scored or burred, they may be cleaned up with emery

cloth.

Examine the rotor shaft serrations for wear, burrs or

Fig. 6 Removing Oil Seal and Bearing from End

peening. Also, inspect the bearing and oil seal contact

Plate with Tool J 6270-3

surfaces of the shafts for wear and scoring.

Inspect the inside surface of the blower housing for

burrs and scoring. The inside surface must be smooth

for efficient operation of the blower. If the inside surface

of the housing is slightly scored or burred, it may be

cleaned up with emery cloth.

10-4-11