TM 5-3895-342-12

checked/inspected.

capacity in the item/system being

CLASS III Leakage of fluid great enough to form

checked/inspected. When in doubt,

drops that fall from the item being

notify your supervisor.

checked/inspected.

When operating with Class I or II leaks,

continue to check fluid levels as

required in your PMCS.

CAUTION

Class III leaks should be corrected

Equipment operation is allowable with

before

releasing

equipment

for

minor leakage (Class I or II). Of course,

operation.

consideration must be given to the fluid

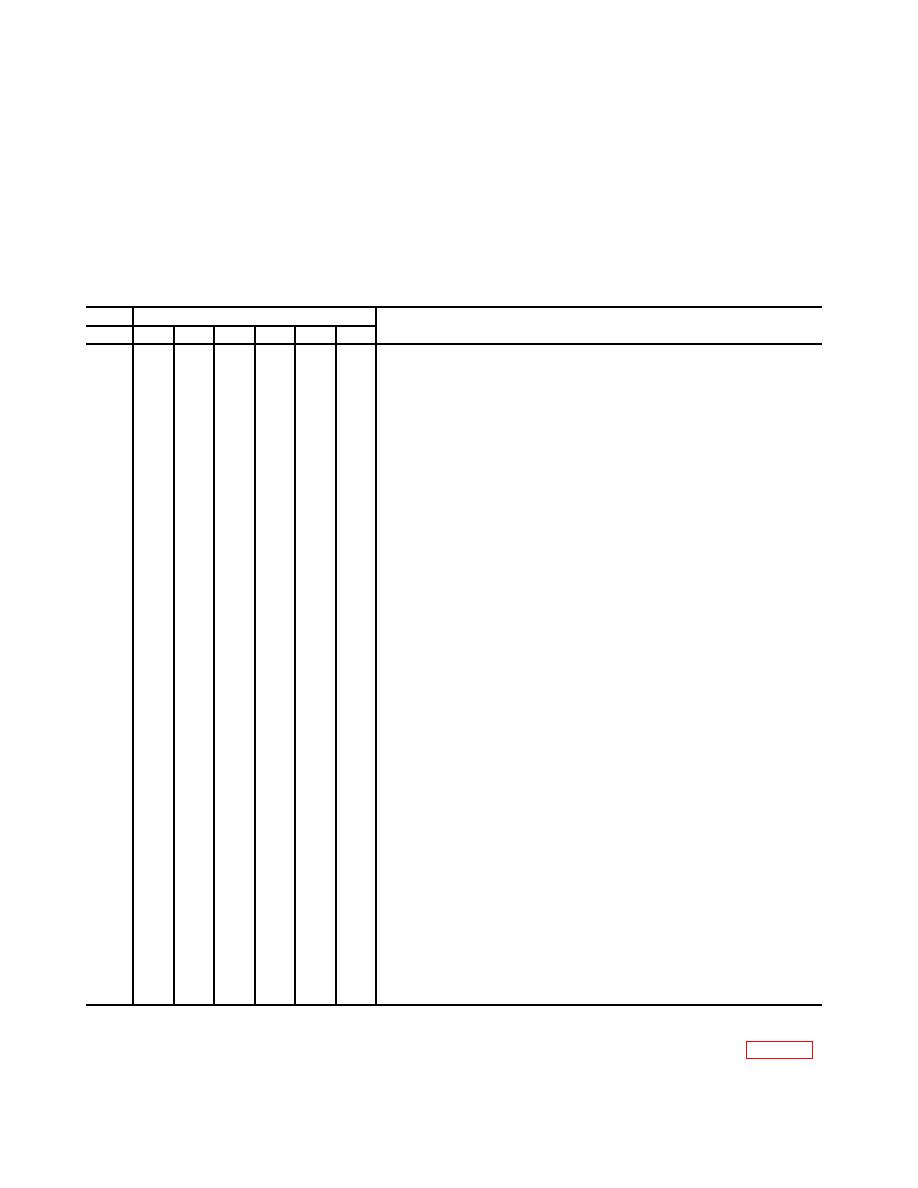

Table 4-1. Organizational Preventive Maintenance Checks and Services

Q-Quarterly

A-Annually

H-Hours

S-Semiannually

B-Biennially

MI-Miles

Item

Interval

ITEM TO BE INSPECTED

No

Q

S

A

B

H

MI

Procedure

NOTE

PERFORM OPERATOR/CREW PMCS PRIOR TO

OR IN CONJUNCTION WITH ORGANIZATIONAL

PMCS.

1

ENGINE

a. Check for loose or missing mounting hardware.

b. Check electrical wiring for damage or loose connections.

2

FLYWHEEL AND AIR SHROUDS

Check the vanes on the flywheel for cracks or breaks. Check

the air shroud for loose mountings, bends, or cracks.

3

VALVE TAPPETS

Inspect valve tappets for proper adjustment. With engine

cold the clearance should be, inlet 0.008 inch and exhaust

0.016 inch.

4

MAGNETO

Remove the end cover and inspect for cracks and corroded

terminals. Examine the breaker points for burning and

pitting. Check breaker point gap, 0.015 inch.

5

SPARK PLUGS AND LEADS

Inspect spark plugs for dirty or broken insulators. Check

spark plug electrode condition and gap, 0.030. Inspect leads

for worn or frayed condition.

6

BATTERIES

Inspect cables for fraying and corrosion. Clean corrosion

from the battery and tighten loose cable clamps. Check

specific gravity of electrolyte in each cell.

7

MASTER CLUTCH

Check the adjustment. The clutch should engage and

disengage freely, hold securely when engaged, and not drag

when disengaged.

8

.

TOWING SAFETY CHAIN

Inspect the safety chain for wear, broken links, and corrosion.

Replace worn or broken chain links.

9

BELTS

Inspect generator, hoist, and pump drive belts for damage

and wear. Replace or adjust as necessary. Proper belt

adjustment will permit a 1/2 inch deflection midway between

SECTION IV. TROUBLESHOOTING

4-6. General

This section provides information useful to diag-

Malfunctions which may occur are listed in table 4-2. A

nosing and correcting unsatisfactory operation or

test or inspection procedure is listed under each

failure of the mixer and its components.

malfunction. The corrective action recommended is

described under the probable cause

Change 2 4-4