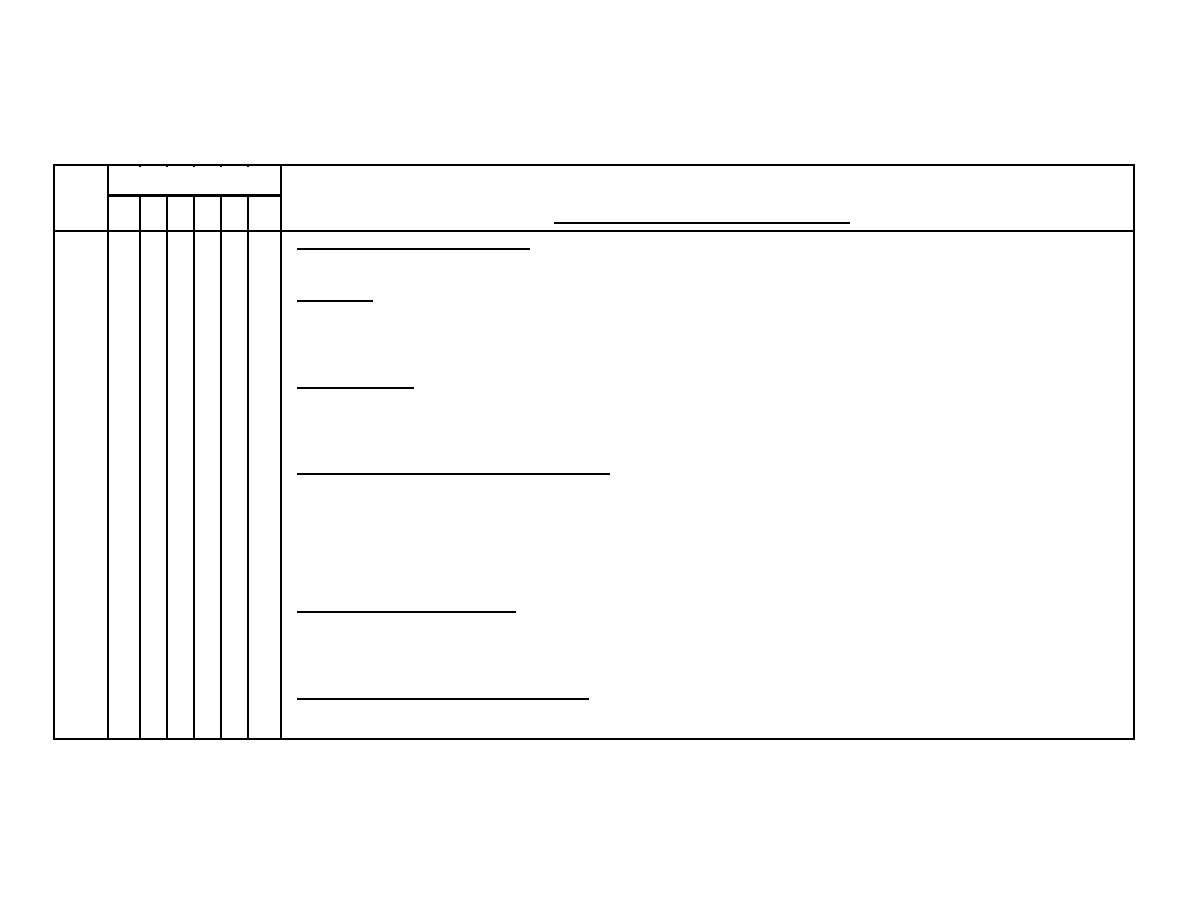

TM 5-3895-359-14&P

ORGANIZATIONAL PREVENTIVE MAINTENANCE CHECKS AND SERVICES

Q-Quarterly

S-Semiannually

A-Annually

B-Biennially

H-Hours

M-Miles

ITEM

INTERVAL

ITEM TO BE INSPECTED

NO

PROCEDURE: Check for and have repaired, filled, or adjusted as needed

Q

S

A

B

H MI

PERFORM ALL OPERATOR PMCS FIRST

8

Cooling and Air Flow (Gas Engine)

X

Clean cylinder and head fins (Ref.

9

Air Cleaner

X

a. Check filter element and clean. (Dry type, Diesel Engine) (Ref.

500

b. Replace filter element (Dry type) (Ref.

X

c. Service oil bath cleaner (Gas Engine) (Ref.

10

Electrical System

X

a. Clean and service batteries (Ref.

X

b. Check wiring harness for corrosion or bare wires.

X

c. Check all lights for proper operation.

11

Transmission Hydraulic Tank and Components

X

a. Check level and inspect for leaks (Ref.

1000

b. Drain fluid, change filters and refill (Ref.

X

c. Inspect hydraulic cylinders for proper operation and leaks. Tighten

leaking packing or report to DS Maintenance. (Ref.

X

d. Inspect pumps and motors for leaks and proper operation. (Ref.

Report defective pumps or motors to DS Maintenance.

12

Steering Pump and Components

X

a. Check fluid level (Ref.

500

b. Drain, flush, refill system.

X

c. Inspect lines and hoses.

13

Final and Tiller Drives, Shafts and Bearings

X

Inspect for proper operation and loose mounting.

J-9