TM 5-3895-359-14&P

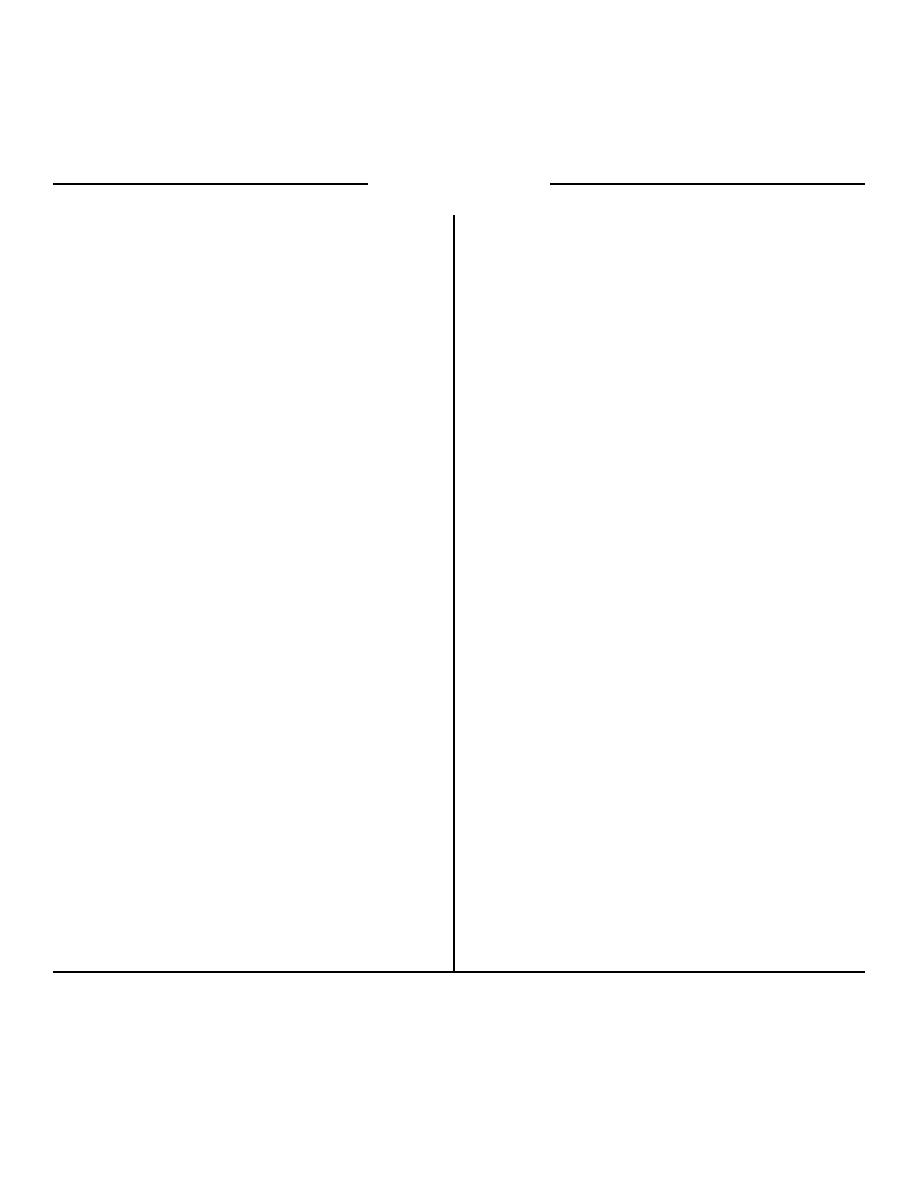

Chart 3

ABNORMAL ENGINE OPERATION

SUGGESTED REMEDY

1. Check the engine coolant temperature gage and, if

Check the compression pressures (consult the Hard

the temperature does not reach 160-185"F (71-85 " )

C

while the engine is operating, consult the Abnormal

Starting chart).

Engine Coolant Temperature chart.

8. Incorrect operation of the engine may result in

2. Check engine fuel spill back and if the return is less

excessive loads on the engine. Operate the engine

than specified, consult the No Fuel or Insufficient Fuel

according to the approved procedures.

chart.

9. Refer to Item 13 on Chart 4.

3. Check the injector timing and the position of the

injector racks. If the engine was not tuned correctly,

10. Check the ambient air temperature. A power

perform an engine tune-up. Erratic engine operation

decrease of .15 to .50 horsepower per cylinder,

may also be caused by leaking injector spray tips.

depending upon injector size, for each 10 (6 )

F

C

Replace the faulty injectors.

temperature rise above 90 (32 ) will occur.

F

C

Relocate the engine air intake to provide a cooler source

4.

Check the compression pressures within the

of air.

cylinders and consult the Hard Starting chart if

11. Engines lose horsepower with increase in altitude.

compression pressures are low.

The percentage of power loss is governed by the

altitude at which the engine is operating.

5. Erratic engine operation may be caused by governor-

to-injector operating linkage bind or by faulty engine

Clean the air box and drain tubes to prevent

tune-up.

Perform the appropriate engine tune-up

accumulations that may be picked up by the air stream

procedure as outlined for the particular governor used.

and enter the engine's cylinders.

Perform an engine tune-up if performance is not

Inspect the blower oil seals by removing the air inlet

satisfactory.

housing and watching through the blower inlet for oil

radiating away from the blower rotor shaft oil seals while

Check the engine gear train timing. An improperly

the engine is running. If oil is passing through the seals,

timed gear train will result in a loss of power due to the

overhaul the blower.

valves and injectors being actuated at the wrong time in

the engine's operating cycle.

Check for a defective blower-to-block gasket. Replace

the gasket, if necessary.

6. Perform a Fuel Flow Test and, if less than the

specified fuel is returning to the fuel tank, consult the No

12. Refer to Item 1 of this chart.

Fuel or Insufficient Fuel chart.

13. Check injector timing and the position of each

7. Check for damaged or dirty air cleaner and clean,

injector rack. Perform an engine tune-up, if necessary.

repair or replace damaged parts.

If the engine is correctly tuned, the erratic operation may

be caused by an injector check valve leaking, spray tip

Remove the air box covers and inspect the cylinder liner

holes enlarged or a broken spray tip. Replace faulty

ports. Clean the ports if they are over 50% plugged.

injectors.

Check for blower air intake obstruction or high exhaust

back pressure. Clean, repair or replace faulty parts.

10-11-19